Yes, you can totally cut PVC with a circular saw! PVC stands for polyvinyl chloride, which is a fancy way of saying it’s a strong and bendy plastic material used for lots of building and DIY projects.

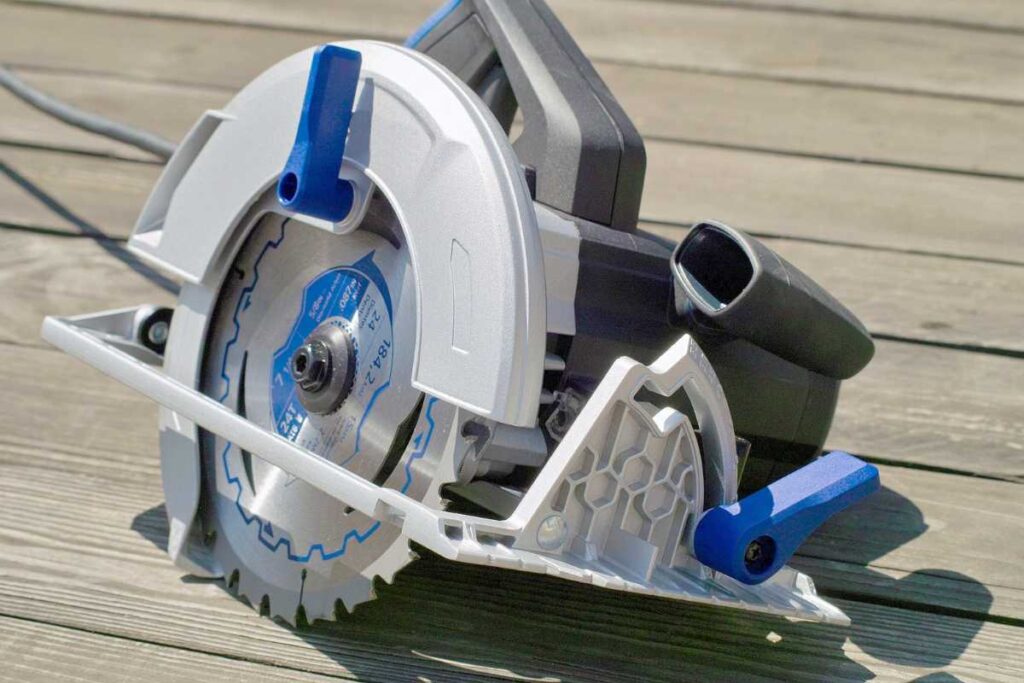

But here’s the cool part: cutting PVC neatly can be a bit tricky without the right tools. That’s where a circular saw comes in handy! With the help of a special blade and some safety gear, you’ll be slicing through PVC pipes like a pro.

In this fun article, we’ll learn all about using a circular saw to cut PVC. We’ll talk about how to stay safe, pick the right blade, use the saw like a champ, get those cuts super clean, avoid common mistakes, and even keep your saw in tip-top shape! Ready to dive in? Let’s go!

What is PVC?

First things first, let’s learn about PVC. Polyvinyl chloride (PVC) is a synthetic plastic polymer commonly used in construction, plumbing, electrical, and other applications. It’s known for its strength, chemical resistance, and affordability, making it a popular choice for various projects.

What Saw Is Best For Cutting PVC?

For cutting PVC, a circular saw with a fine-toothed blade is the best choice. These blades are specifically designed to make clean and precise cuts in plastic materials like PVC. Just make sure to select a blade with the right number of teeth per inch (TPI) for your project to ensure smooth cutting without chipping or melting the PVC.

Can I Use A Circular Saw To Cut PVC Pipe?

Absolutely! A circular saw is a great tool for cutting PVC pipe. Just make sure to use a fine-toothed blade and secure the pipe firmly before cutting. Always wear safety goggles and follow proper safety precautions.

Can You Cut PVC Sheet With Circular Saw?

Yes, you can definitely cut PVC sheets with a circular saw! A circular saw equipped with a fine-toothed blade is perfect for cutting PVC sheets, providing clean and precise cuts.

Just make sure to secure the sheet firmly before cutting and wear appropriate safety gear, such as goggles and gloves, to protect yourself from any debris.

With the right technique and precautions, you’ll be able to cut PVC sheets like a pro!

Benefits And Drawbacks Of Using A Circular Saw For Cutting PVC

Do you have a DIY project that involves cutting PVC pipes? Are you wondering if a circular saw is a suitable tool for the job?

When the answer is yes, you can surely use a circular saw to cut PVC, but before that, it is essential to know the advantages and disadvantages of using it.

Benefits Of Using A Circular Saw For Cutting PVC:

Using a circular saw for cutting PVC has several benefits, such as:

- Efficiency: Circular saws are fast and efficient, allowing you to make quick cuts through PVC pipes or sheets.

- Accuracy: With the right blade and technique, circular saws can provide precise cuts, ensuring your PVC pieces fit together perfectly.

- Versatility: Circular saws are versatile tools that can handle various materials, making them useful for a wide range of DIY projects.

Drawbacks Of Using A Circular Saw For Cutting PVC:

Before cutting PVC pipes with a circular saw, it’s essential to understand the potential risks and hazards. Some of the risks and hazards include:

- Risk of Melting: If the blade generates too much heat, it can melt the PVC, leading to messy cuts and potentially damaging the material.

- Flying debris: Cutting PVC pipes can produce small bits and pieces that can fly off in different directions and cause injury if proper safety measures are not taken.

- Safety Concerns: Circular saws can be dangerous if not used properly. There’s a risk of kickback or injury if the saw binds or if proper safety precautions aren’t followed.

- Noise and Vibration: Circular saws can be noisy and produce vibrations, which may be uncomfortable or disruptive, especially if you’re working for extended periods.

Overall, while circular saws are effective for cutting PVC, it’s essential to use the right blade, follow safety protocols, and be mindful of potential drawbacks to achieve the best results.

What Kind Of Circular Saw Blade To Cut PVC?

You can’t use a regular circular saw blade to cut PVC. PVC melts easily, and the heat generated by a regular blade would cause the PVC to melt and gum up the blade, making for a poor cut.

For PVC, you’ll need a special Fine-Tooth Circular Saw Blade with High Grind (TCG) for plastics. These blades have more teeth (typically 60–80 teeth per inch) than a standard wood cutting blade, which reduces chipping and creates a cleaner cut. They also have high-heat-resistant teeth to prevent melting.

Here are some other things to keep in mind when cutting PVC with a circular saw:

- Use a sharp blade: A dull blade will generate more heat and make it more likely for the PVC to melt.

- Reduce cutting speed: Slow down the saw to minimize heat generation.

- Use a lubricant: A lubricant such as WD-40 can help to keep the blade cool and prevent melting.

- Clamp down the PVC: Make sure the PVC is securely clamped in place to prevent it from moving while you cut.

Using the right blade will ensure that your PVC cutting projects turn out clean and professional-looking.

Safety Measures To Take When Cutting PVC With A Circular Saw

To reduce the risks and hazards associated with cutting PVC pipes with a circular saw, it’s essential to take the following safety measures:

- Wear protective gear: Always wear safety glasses, gloves, and earplugs when operating a circular saw.

- Secure the PVC pipe: Use a vise or other clamping mechanism to secure the PVC pipe in place when cutting.

- Use a suitable blade: Use a blade specifically designed for cutting PVC pipes to reduce the risk of kickback.

- Mark the cutting line: Mark the cutting line on the PVC pipe to ensure accuracy and prevent kickback.

- Cut slowly: Cut the PVC pipe slowly to reduce the risk of kickback and ensure smooth cuts.

- Allow the blade to cool down: Allow the blade to cool down before touching it to reduce the risk of burns.

Preparing To Cut PVC With A Circular Saw

Before cutting PVC, prepare your circular saw by adjusting the blade height to the appropriate depth. Ensure the blade is aligned correctly with the cutting line to prevent wandering or veering off course during the cut.

Follow these guidelines to prepare for cutting.

Measuring And Marking The PVC

Measuring and marking the PVC pipe is a crucial step to ensure precision when cutting. To mark and measure your object, consider the following steps:

- Measure the PVC pipe carefully using a measuring tape or ruler to determine the exact length you require for the job.

- Mark the PVC pipe using a pencil or marker. Label each measure point precisely to avoid confusion while cutting.

Clamping The PVC To The Workbench

Clamping the PVC pipe to the workbench is an integral part of cutting. Here’s why:

- Clamping helps prevent the PVC pipe from shifting while you cut, ensuring accuracy.

- Without clamping, there’s a risk of the saw blade catching the pipe and damaging it.

Best Practices to Follow When Clamping PVC:

- Use a strong clamp that is the appropriate size for the PVC pipe.

- Clamp the pipe securely, so it doesn’t move or shift during cutting.

- If possible, use a clamp on either side of the blade to keep the pipe from rotating.

Techniques For Cutting PVC With A Circular Saw

There are several techniques you can use to cut PVC with a circular saw, depending on the desired outcome:

- Straight cuts: For basic cuts, use a straight edge or guide to ensure a straight and accurate cut.

- Bevel cuts: Adjust the saw’s bevel angle to create angled cuts for mitre joints or decorative purposes.

- Mitre cuts: Use a mitre saw attachment or jig to create precise angled cuts for corners or joints.

Tips For Smooth And Clean Cuts

To achieve smooth and clean cuts when working with PVC and a circular saw, consider the following tips:

- Maintain a consistent cutting speed to prevent melting or chipping.

- Provide adequate support for the PVC material to minimize vibration and ensure a straight cut.

- Avoid overheating by periodically pausing to allow the blade and material to cool.

Common Mistakes to Avoid

When cutting PVC with a circular saw, avoid these common mistakes:

- Using incorrect blade types, such as wood-cutting blades, can result in jagged cuts or melted edges.

- Ignoring safety precautions such as measuring and marking the PVC pipe or securely clamping it with the workbench can lead to accidents or injury.

- Rushing the cutting process can result in uneven or inaccurate cuts.

Finishing The Cut PVC

PVC pipes are a popular option for many DIY projects, and it’s essential to know how to finish the cut smoothly and effectively. If you’re using a circular saw for cutting PVC pipes, there are a few things you need to keep in mind before starting.

Removing Burrs And Rough Edges

Once you have finished cutting your PVC pipes, you may notice that the edges are not as smooth as you would like them to be. That’s where removing burrs and rough edges comes into play. Burrs are tiny metal bits that form on the edges of the PVC pipe, and they can cause damage if not removed.

There are several tools that you can use for removing burrs and rough edges from your PVC pipes, including:

- Utility knife: Use an angled edge of the blade to remove the burrs carefully.

- Sandpaper: Use a sanding block or fine-grip sandpaper to smooth the edges of the pipe.

- Deburring tool: A deburring tool is a specific tool designed for removing burrs and rough edges from PVC pipes.

Sanding And Smoothing The Edges

Smoothing the edges of your PVC pipes is vital for a few reasons. First, it reduces the risk of injury. Secondly, it ensures that your PVC pipe fits snugly with other pipes and fittings. Thirdly, it provides a more professional look to your DIY project.

Here are a few tips on how you can do it:

- Wrap the sandpaper around the pipe and move it backward and forward smoothly.

- Rotate the PVC pipe and repeat the sanding process.

- Use a finer-grit sandpaper to achieve a smoother finish.

Maintaining Your Circular Saw

Proper maintenance of your circular saw is essential for optimal performance and longevity. Regularly inspect and sharpen the blade as needed to ensure clean and efficient cuts. Additionally, clean the saw and remove any debris or buildup to prevent malfunctions.

How To Cut PVC Pipe Lengthwise By Hand?

Cutting PVC pipe lengthwise by hand is fun, and you can do it as follows:

- Mark the cutting line along the length of the pipe.

- Score the marked line with a sharp utility knife, making multiple passes until you create a groove.

- Carefully cut along the scored line using a handsaw, maintaining a steady hand to ensure a straight cut.

- Smooth out any rough edges with sandpaper for a clean finish.

Can You Cut PVC With A Miter Saw?

Yes, you can cut PVC with a miter saw. Use a fine-toothed blade designed for cutting plastic materials, and ensure the PVC is securely clamped in place before making the cut. Always wear safety goggles and follow proper precautions.

How To Cut PVC Pipe Without A Saw?

You can cut PVC pipe without a saw using alternative methods:

- Hacksaw: Score the pipe with a hacksaw and carefully snap it along the scored line.

- Pipe Cutter: Use a PVC pipe cutter to make clean cuts without the need for a saw.

- Heat Gun: Soften the PVC with a heat gun and then cut through it with a utility knife or scissors.

Always prioritize safety and use appropriate tools for the job.

Can You Cut PVC With Hacksaw?

Yes, you can cut PVC with a hacksaw. Choose a hacksaw blade with fine teeth and carefully score the PVC along the cutting line. Apply even pressure as you saw through the pipe, and wear safety goggles to protect your eyes from debris.

Can You Cut PVC With Sawzall?

Yes, you can cut PVC with a Sawzall (reciprocating saw). Use a fine-toothed blade designed for cutting plastic materials, and ensure the PVC is securely clamped in place before making the cut.

Can You Use A Jigsaw To Cut PVC Pipe?

Yes, you can use a jigsaw to cut PVC pipe. Use a fine-toothed blade designed for cutting plastic materials, and ensure the PVC is securely clamped in place before making the cut.

How To Cut 4 Inch PVC Pipe?

To cut a 4-inch PVC pipe, follow these steps:

- Measure and Mark: Measure and mark the cutting line around the circumference of the pipe.

- Secure: Secure the pipe firmly using clamps or a vise to prevent it from moving during cutting.

- Cutting Method: Choose your preferred cutting method, such as using a handsaw, hacksaw, miter saw, or PVC pipe cutter.

- Cutting: Carefully cut along the marked line, ensuring a straight and clean cut.

- Deburring: Use sandpaper or a deburring tool to remove any rough edges and ensure a smooth finish.

Best Saw To Cut PVC Pipe

The best saw to cut PVC pipe depends on personal preference and the specific project requirements. Common options include:

- Circular Saw: Ideal for straight cuts on PVC pipes, especially when equipped with a fine-toothed blade. I’m currently using a DEWALT 7-1/4-inch circular saw for various purposes. It is lightweight and powerful. You can check it out by clicking here.

- Miter Saw: Great for making precise angle cuts on PVC pipes, ensuring accurate fittings. If you wish, you can check out the DEWALT 12-Inch Miter Saw for your various bevel and miter cutting purposes.

- Hacksaw: Handy for cutting PVC pipes in tight spaces or when a power saw isn’t available. Using a hacksaw is also an inexpensive option, and you can check out the Craftsman Hand Saw with a 12-inch hacksaw blade.

- Reciprocating Saw (Sawzall): Useful for cutting through PVC pipes quickly, particularly in demolition or renovation projects. It’s a must-have tool for every homeowner and DIY renovation worker. For the best performance, you can check out the 20V Cordless Reciprocating Saw from BLACK & DECKER.

Choose the saw that best suits your needs, and always prioritize safety while working.

Conclusion

In conclusion, cutting PVC with a circular saw is entirely possible with the right tools, techniques, and safety precautions.

By selecting the appropriate blade, preparing the saw correctly, and using proper cutting techniques, you can achieve clean and precise cuts for your PVC projects.

Remember to prioritize safety at all times and maintain your circular saw for optimal performance.

Recent Posts

Woodworking in 2025 is all about efficiency, precision, and smart technology. Whether you're a beginner or a seasoned craftsman, having the right tools can make all the difference. Here are the top 7...

Ever tried drilling into a piece of wood only to end up with a splintered mess or a wobbly hole? Yeah, it's more common than you think. Wood might seem like an easy material to work with, but...