A pneumatic nail gun works by using compressed air to drive nails into materials. When the trigger is pulled, the compressed air is released, pushing the piston forward and driving the nail into the surface.

These tools are especially useful for fast and efficient construction work, as they can drive nails quickly and accurately without requiring much physical effort. Additionally, pneumatic nail guns are versatile and can be used for a range of tasks, including framing, roofing, and finishing work.

With the proper safety precautions, such as wearing eye and ear protection, pneumatic nail guns are a valuable tool for any construction project.

What Is A Pneumatic Nail Gun?

Pneumatic nail guns, also known as an air nailer, are powerful and versatile tools that are widely used in construction and woodworking. They are powered by compressed air and use a piston-driven mechanism to drive nails into a variety of surfaces.

When the trigger is pulled, compressed air is released and drive a piston inside the nail gun. This rapid motion propels a nail through the gun and into the material being fastened.

Pneumatic nail guns are commonly used in construction and woodworking for their efficiency, power, and continuous operation, as long as there is a stable supply of compressed air.

What Is One Advantage Of A Pneumatic Nail Gun?

One advantage of a pneumatic nail gun is its consistent and powerful performance, making it suitable for heavy-duty applications in construction and woodworking.

The continuous supply of compressed air allows for rapid and efficient nailing without the need for frequent recharging or battery replacements.

Comparison with Other Nail Gun Types

Pneumatic nail guns stand out among their counterparts, such as electric and gas-powered models. While each type has its advantages, pneumatic nail guns are favored for their reliability, affordability, and ease of use. Comparing these options helps users make informed decisions based on their specific needs.

Mechanism Of A Pneumatic Nail Gun

A pneumatic nail gun is a handy gadget for construction, woodworking, and other projects where hammering nails by hand might be tedious or impractical.

Here we will describe the mechanism of a pneumatic nailer to understand how it works:

The Power Source:

Air Compressor: Pneumatic nail guns require a constant supply of compressed air, typically from an air compressor. The compressor pumps air into a storage tank, building up pressure.

Air Hose: A flexible hose connects the compressor to the nail gun, channeling the compressed air.

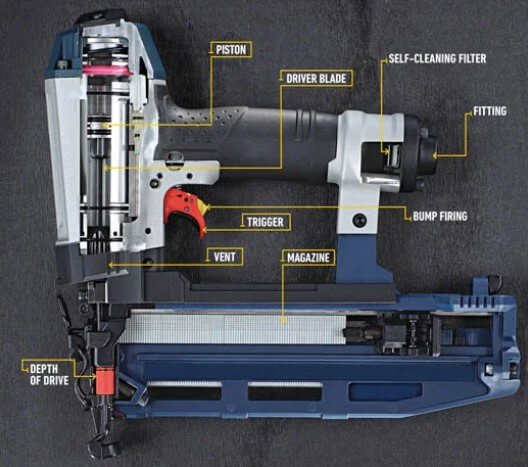

Inside the Nail Gun:

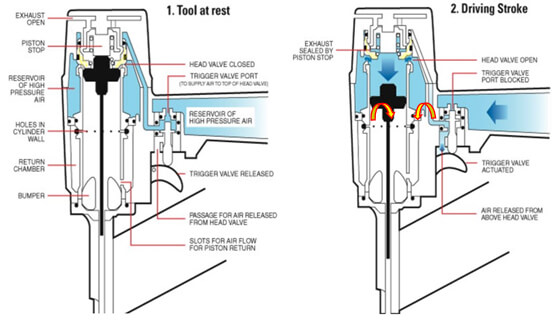

Air Reservoir: Once air enters the nail gun, it’s stored in a small chamber called the air reservoir.

Trigger & Valve: Pulling the trigger opens a valve, allowing pressurized air to flow from the reservoir.

Piston & Driver: The air pressure pushes a piston down a cylinder. Attached to the piston is a long metal shaft called the driver, which makes contact with the nail head.

Nail Magazine: Nails are loaded into a magazine within the gun, typically collated (stuck together) for convenience.

Firing the Nail:

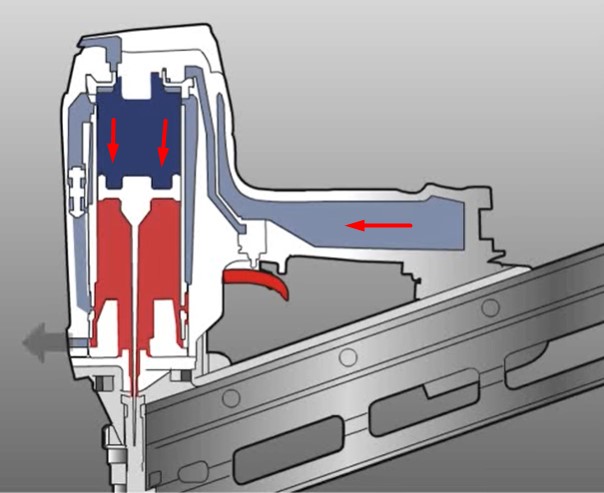

Air Pressure & Piston Movement: When the trigger is pulled, the air pressure forces the piston and driver down the cylinder.

Nail Propulsion: The driver slams into the nail head, propelling it out of the magazine and down the barrel of the gun.

Safety Mechanism: Most nail guns have a safety mechanism that prevents firing unless the nose of the gun is pressed against the work surface. This helps prevent accidental nail discharge.

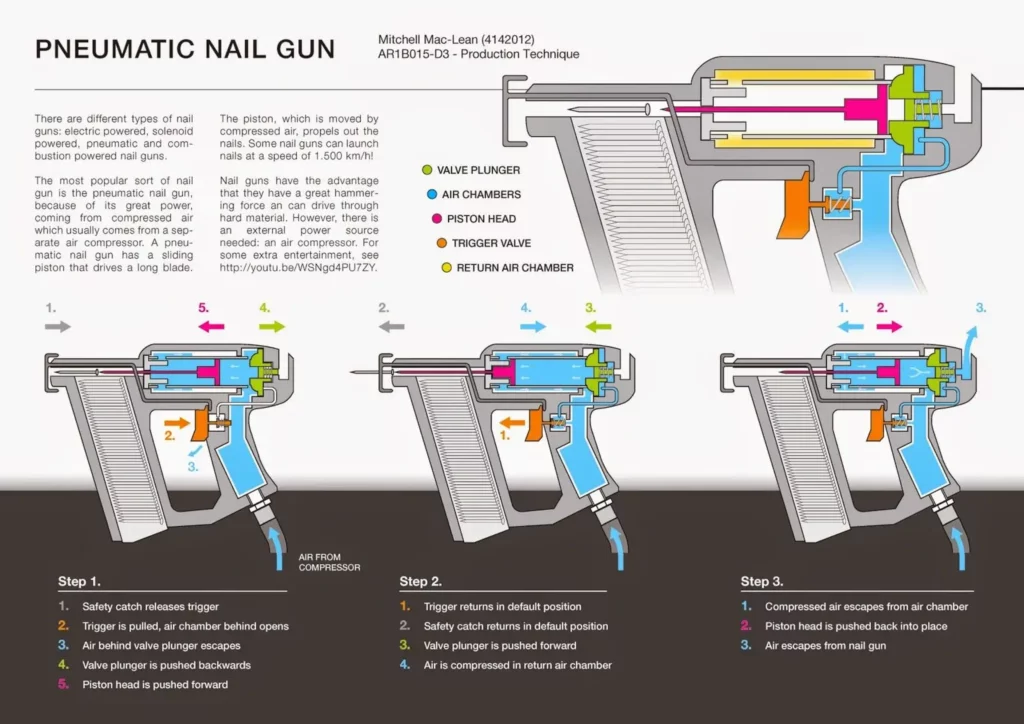

How Does A Pneumatic Nail Gun Work Step By Step?

Here is a step-by-step explanation of how a pneumatic nail gun works:

Loading: Begin by loading the appropriate nails into the magazine of the nail gun. The magazine is a chamber that holds a strip or coil of nails.

Connection to Air Compressor: Attach the pneumatic nail gun to an air compressor using a hose. The air compressor supplies the compressed air needed for the nail gun to operate.

Adjustments: Set the depth adjustment on the nail gun if available. This controls how deeply the nails will be driven into the material.

Trigger Activation: Press the trigger of the nail gun to activate the firing sequence.

Release of Compressed Air: When the trigger is pulled, the pneumatic nail gun releases a burst of compressed air from the air compressor.

Piston Movement: The released compressed air drives a piston or driver blade inside the nail gun forward at high speed.

Nail Firing: As the piston moves forward, it strikes the back of the nail in the firing chamber, propelling the nail out of the gun and into the material being fastened.

Repeatable Process: The user can repeat the process by releasing the trigger, repositioning the nail gun, and pulling the trigger again for subsequent nail placements.

Safety Mechanisms: Pneumatic nail guns often incorporate safety features, such as a tip or nose that must be pressed against a surface before firing, and anti-dry fire mechanisms to prevent firing when no nails are present.

Continuous Operation: As long as there is a continuous supply of compressed air from the air compressor, the pneumatic nail gun can operate continuously, making it suitable for high-volume and repetitive tasks.

In summary, a pneumatic nail gun utilizes compressed air to drive a piston, which in turn propels nails into a material. This process allows for efficient and rapid fastening in various construction and woodworking applications.

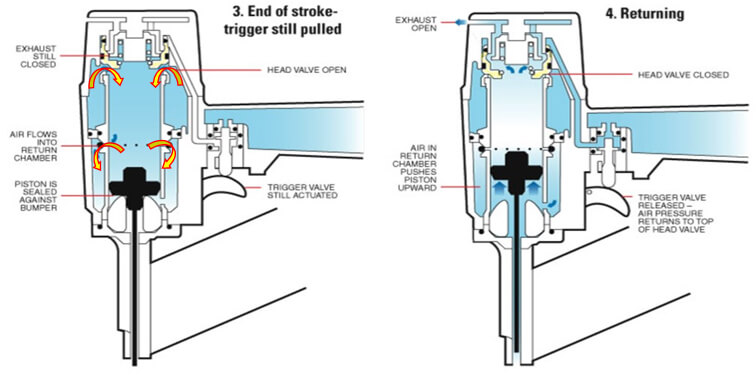

How Does A Pneumatic Nail Gun Work Diagram

How The Air Pressure Is Used To Drive The Nails?

Pneumatic nail guns are handheld tools that require compressed air to force nails into a given surface. The air compressor is attached to the nail gun, and it connected to the gun via a hose. The compressed air produced by the air compressor will be stored in a chamber inside the nail gun.

When the trigger is pressed, a valve is opened, and compressed air flows into the nail gun’s chamber, which initiates a piston. The piston drives the nail into the workpiece with considerable force using this compressed air.

When the piston returns to its starting position, the nail magazine feeds additional nails into the gun’s chamber for future use.

How The Trigger Controls The Release Of Air Pressure?

The trigger is one of the most critical components of a pneumatic nail gun. When the trigger is pressed, it opens the valve, which allows compressed air to flow into the gun. The valve remains open for a short period, allowing the air pressure built up in the chamber to drive the nail into the workpiece.

When the trigger is released, the valve will shut off, and the compressed air supply will stop flowing, ending the piston’s driving force. This trigger mechanism enables users to control the depth of the nail in the workpiece and ensure precision in their work.

Pneumatic nail guns are convenient power tools used in woodworking for quick and efficient nailing. Understanding the mechanism of action, operation, and control of a pneumatic nail gun can help users achieve excellent results in their woodworking projects.

How Is A Pneumatic Nail Gun Powered?

A pneumatic nail gun operates by utilizing compressed air generated by an air compressor, which serves as the system’s powerhouse. Compressing air to a high pressure (typically 70-90 PSI), the compressor stores it in a tank.

Connected to the gun via a flexible hose, the trigger’s action opens a valve, allowing pressurized air to flow into the gun’s internal chamber. This compressed air drives a piston connected to a metal shaft, or driver, responsible for striking and firing the nail.

Thus, the pneumatic nail gun’s power source is the stored pressure in the compressed air, with the trigger and valve mechanism controlling its flow to execute the nailing process.

What Do You Need For A Pneumatic Nail Gun?

To use a pneumatic nail gun, you need the following:

Pneumatic Nail Gun: The tool itself, designed for various fastening applications.

Air Compressor: The compressor generates and stores compressed air to power the nail gun.

Air Hose: A flexible hose connects the nail gun to the air compressor, allowing the flow of compressed air.

Nails: Properly sized nails compatible with the nail gun’s magazine or strip, loaded into the gun for fastening tasks.

Safety Gear: Safety glasses and hearing protection are advisable for personal protection.

Ensure that the air compressor is appropriately sized for the nail gun’s requirements, and follow safety guidelines during operation.

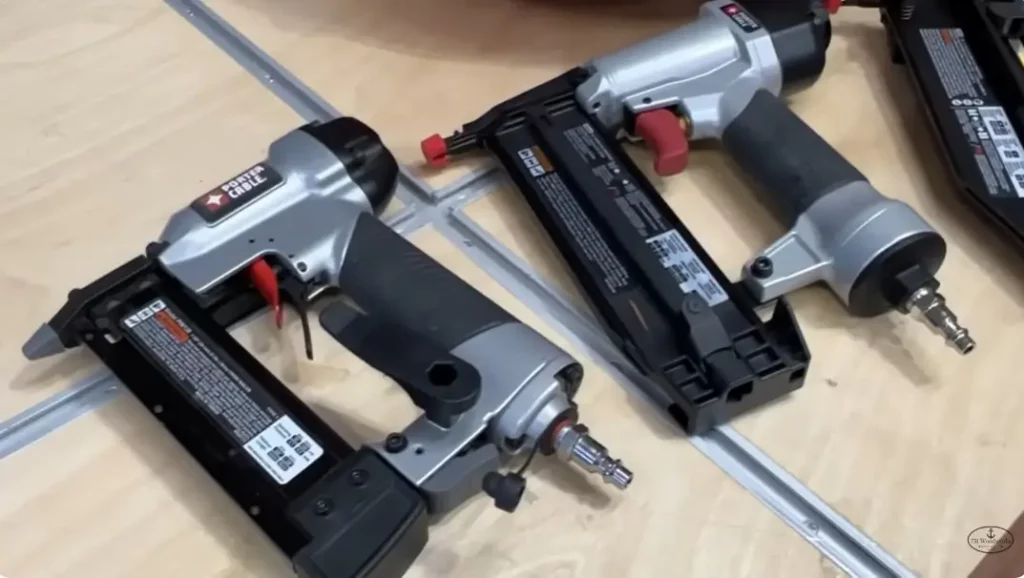

Types Of Pneumatic Nail Guns

Based on the uses, speed and accuracy, pneumatic nail gun can be different types. Though, all follow the same principal, knowing the types may help choosing the right one for the project you’re going to handle and how they work.

Here, we will discuss the different types of pneumatic nail guns available in the market, their pros and cons, and their specific uses.

There are four main types of pneumatic nail guns on the market, each designed for specific tasks:

Brad nailer: Brad nailers are used for delicate woodworking projects that require precise, small nails. They are ideal for installing trim, decorative molding, and other finishing work. Brad nailers use 18-gauge nails, which are thinner and shorter than other types of nails.

Framing nailer: Framing nailers, also called nail guns, are designed for heavy-duty tasks such as building houses, decks, and fences. They are capable of firing large, thick nails up to 3.5 inches in length and can handle thicker materials such as hardwood and dense lumber.

Finish nailer: Finish nailers are used for detailed and precise finishing work such as installing crown molding, baseboards, and window casings. They use 15- or 16-gauge nails, which are thicker and stronger than brad nails, but not as thick as framing nails.

Palm nailer: Palm nailers are compact and lightweight, fitting comfortably in your hand. They are designed for tight spaces and nail jobs where a standard nail gun cannot reach. Palm nailers use small nails up to 3.5 inches in length and are great for small projects such as framing and decking.

How To Use A Pneumatic Nail Gun?

Load nails, connect to an air compressor, adjust depth if necessary, press the trigger against the surface, and release to drive nails. Ensure safety precautions and follow manufacturer guidelines.

For the details step by step guide, you can read our articles on it by clicking on this link.

What Are The Uses Of Pneumatic Nailers?

Pneumatic nailers are versatile tools widely used in various applications, including:

Construction Framing: Pneumatic framing nailers are commonly employed in the construction of wooden structures, such as framing walls and roofs.

Finish Carpentry: Pneumatic finish nailers are used for trim work, crown molding, baseboards, and other detailed carpentry tasks, providing a clean and professional finish.

Woodworking: Pneumatic nailers are valuable in woodworking projects for assembling furniture, cabinets, and other wooden structures with precision and efficiency.

Roofing: Roofing nailers are specialized pneumatic tools designed for attaching shingles or roofing materials to roof decks, streamlining the roofing process.

Siding Installation: Pneumatic siding nailers are used in the installation of siding materials, facilitating a secure and uniform attachment to the exterior of buildings.

Fencing: Pneumatic nailers are employed in fencing projects for attaching pickets, rails, and other components, ensuring a sturdy and durable fence assembly.

Subflooring: Pneumatic flooring nailers are utilized in installing subflooring, providing a quick and reliable method for securing plywood or oriented strand board to floor joists.

Decking: Pneumatic nailers are instrumental in building decks by efficiently attaching deck boards to the underlying structure.

In summary, pneumatic nailers find applications in a wide range of construction and woodworking tasks, offering speed, precision, and reliability in fastening various materials.

Maintenance And Safety Tips

Pneumatic nail guns offer a fast and efficient way to complete nailing on wood surfaces. Using compressed air, these nail guns drive nails into the wood without damaging the surface compared to traditional nailing methods.

However, just like any tool, they require proper maintenance and knowledge of safety practices to ensure they function optimally and remain safe to use.

Here, we will discuss the recommended maintenance practices, safety tips, and troubleshooting common problems while using a pneumatic nail gun.

Regular Maintenance Practices

Regular maintenance is vital for keeping your pneumatic nail gun in excellent working condition. Below are some recommended maintenance practices:

- Lubrication: Regular lubrication of the nail gun’s moving parts and air fittings helps improve the tool’s performance. Use lightweight oil (air tool oil) to lubricate the nail gun’s moving parts as per the manufacturer’s recommendation.

- Cleaning: After every use, it is essential to remove the remaining nails and debris from the nail gun. This helps prevent clogging within the tool, which could damage its internal parts. A damp cloth is sufficient to clean the exterior of the nail gun.

- Inspection: As part of regular maintenance, inspect the nail gun’s components for any signs of wear or damage. Damaged or worn out parts should be replaced immediately with manufacturer-recommended parts.

- Storage: Proper storage is equally important as maintenance. Store the nail gun in a cool, dry place, and away from direct sunlight or heat. Cover the nail gun when not in use to protect it from dust and debris.

Safety Tips For Working With A Pneumatic Nail Gun

Using a pneumatic nail gun can be dangerous if not handled with care. Here are some safety tips to keep in mind when working with a pneumatic nail gun.

- Wear protective gear: Always wear eye protection and hearing protection when using a pneumatic nail gun. Wear gloves to protect your hands from flying debris and the nail gun’s sharp components.

- Proper handling: Always handle the nail gun with care. Never point the nail gun at yourself or anyone else, even if the gun is not loaded. Keep your fingers off the trigger until you are ready to use the nail gun, and never carry the nail gun with your finger on the trigger.

- Secure the workpiece: Ensure that the workpiece is securely clamped or held in place before nailing. This helps prevent the wood surface from shifting and causing a nail to miss its target.

- Proper loading: Ensure that you use the right size and type of nails for the job and that the nail gun is properly loaded. Incorrect loading could cause jamming, misfires, and damage to the internal components.

- Power source: Always power off the nail gun and disconnect it from the power source when making adjustments, loading nails, or changing components.

Troubleshoot Common Problems

Despite regular maintenance and safe use, pneumatic nail guns can experience some problems while in use. Here are some common issues and how to troubleshoot them:

- Misfiring: Misfiring occurs when the nail gun fails to drive a nail into its target upon firing. Check the air compressor’s pressure, the nail loading, and the condition of the driver blade. Adjust or replace if necessary.

- Jamming: Jamming occurs when the nails get stuck inside the nail gun. Check if the nails are the right size and type, properly loaded, or if any debris is present within the nail gun’s components. Clear any blockages, reload your nail gun, and try again.

- Leaking: Leaking occurs when the nail gun is losing pressure through air leaks. Check all seals and air fittings for damage, and replace as necessary. Tighten loose components and ensure your nail gun is lubricated before use.

Understanding how to maintain and safely operate a pneumatic nail gun can make your nailing tasks easier, faster, and more efficient.

Adhere to the recommended maintenance practices, apply the safety tips and troubleshoot common problems, and you’ll enjoy a seamless, hassle-free nailing experience.

Environmental Impact Of Using A Pneumatic Nailer

It’s crucial to consider the environmental impact of tool usage. Pneumatic nail guns, powered by compressed air, are relatively eco-friendly compared to gas-powered alternatives. Adhering to sustainable practices in construction contributes to a greener future.

Future Technological Developments

As technology advances, pneumatic nail guns continue to evolve. Innovations in design, materials, and power sources are on the horizon. Keeping an eye on these developments ensures users stay at the forefront of the industry.

FAQs: How Does A Pneumatic Nail Gun Work?

Are pneumatic nail guns suitable for DIY projects?

Pneumatic nail guns are versatile and can be used for a wide range of DIY projects, from simple repairs to more complex woodworking tasks.

Do You Need To Put Oil In A Pneumatic Nail Gun?

Yes, it is recommended to regularly lubricate a pneumatic nail gun with pneumatic tool oil to ensure smooth operation and prevent wear.

What Are The Advantages Of Using A Pneumatic Nail Gun?

Pneumatic nail guns are faster and more efficient than using a hammer and nails.

What Kind Of Air Compressor Works With A Nail Gun?

A compressor with at least 2 gallons of air tank capacity works with a pneumatic nail gun.

What Size Nails Can A Pneumatic Nail Gun Use?

The size of the nail that a pneumatic nail gun can use depends on the nail gun itself, but typically ranges from 1 to 3. 5 inches.

Are Pneumatic Nail Guns Dangerous?

Pneumatic nail guns can be dangerous if not used properly, and proper safety precautions should always be taken.

Conclusion

Overall, the pneumatic nail gun is a powerful and efficient tool that simplifies nailing tasks, saves time, and increases productivity. The design of pneumatic nail guns is based on simple principles of physics, which results in a well-coordinated process that speeds up construction work.

Pneumatic nail guns operate by utilizing compressed air to generate propulsion, which drives nails into surfaces with ease and precision. Operators need to be mindful of safety precautions when using the tool, including wearing protective gear and following manufacturer recommendations.

With pneumatic nail guns, users can effortlessly install nails into wood, plaster, drywall, and other materials, substantially reducing the effort and time investment required for traditional hammering techniques. Suppose you are a construction or DIY enthusiast looking for an effortless, safe, and cost-effective way to drive nails.

In that case, you can consider getting a pneumatic nail gun, which is ideal for small and large-scale projects alike.

Recent Posts

15 Ga vs 16 Ga Finish Nailer: Which One Is Right for Your Project?

If you're diving into the world of finish carpentry or simply trying to upgrade your home tool kit, you've probably run into the question: 15 ga vs 16 ga finish nailer—what’s the big deal? They...

Woodworking in 2025 is all about efficiency, precision, and smart technology. Whether you're a beginner or a seasoned craftsman, having the right tools can make all the difference. Here are the top 7...