To cut straight with a reciprocating saw, use a guide or hold the saw steady with both hands. For a cleaner cut, select the right blade for the material you are cutting.

Reciprocating saws are versatile tools that are commonly used in construction, woodworking, and demolition. One of the challenging things about using a reciprocating saw is getting a straight cut. It takes practice and experience to master it, but with some essential tips, you can achieve a cleaner and more precise cut.

This article will guide you through the steps to cut straight with a reciprocating saw and provide you with some useful information to get you started.

Understanding The Reciprocating Saw

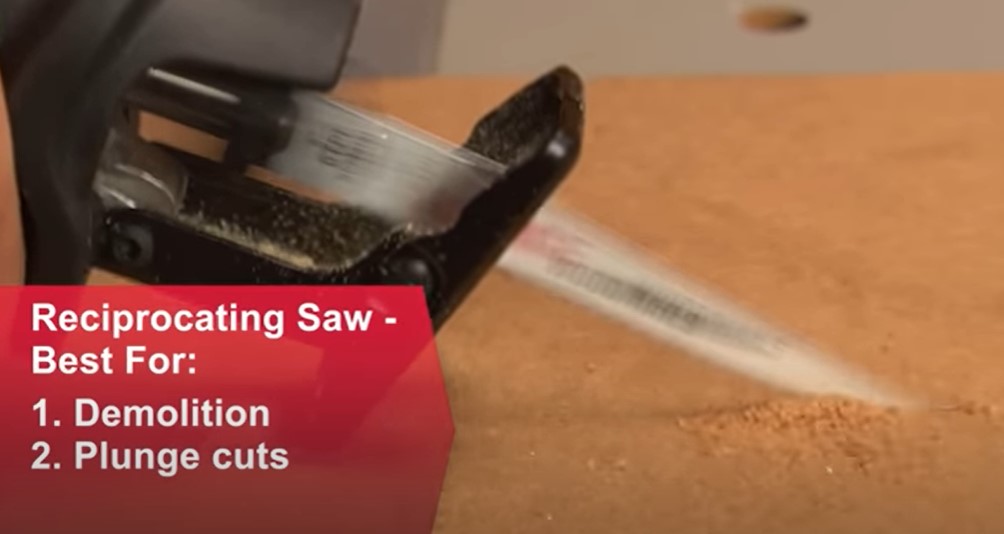

A reciprocating saw is an electric saw designed for cutting through a variety of materials. Its back-and-forth blade motion makes it ideal for demolition, pruning, and remodeling projects.

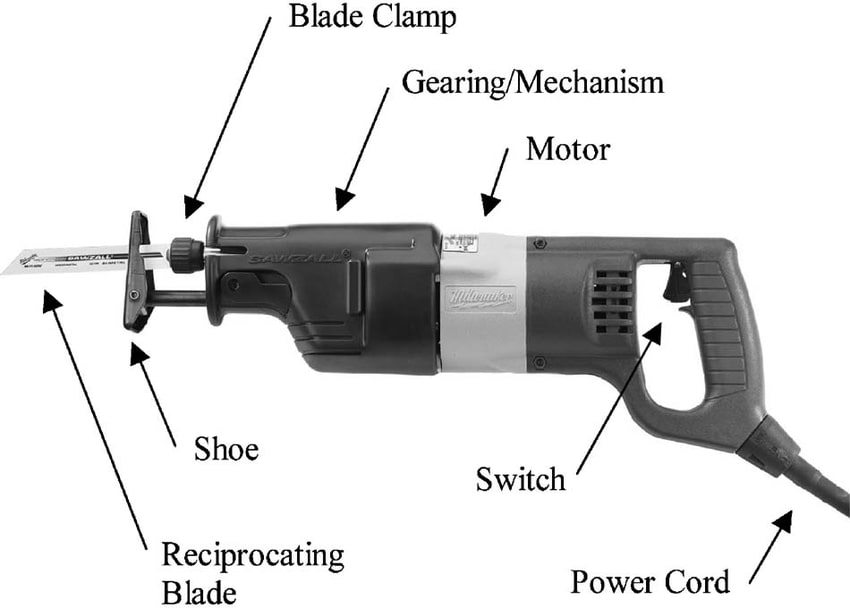

Parts Of A Reciprocating Saw

A reciprocating saw typically consists of the following components:

- Body: This is the main part of the saw that houses the motor, switch, and blade clamp.

- Motor: The motor is the power source that drives the blade back and forth.

- Switch: The switch controls the on/off function of the saw.

- Blade clamp: The blade clamp holds the blade in place and allows for quick and easy blade changes.

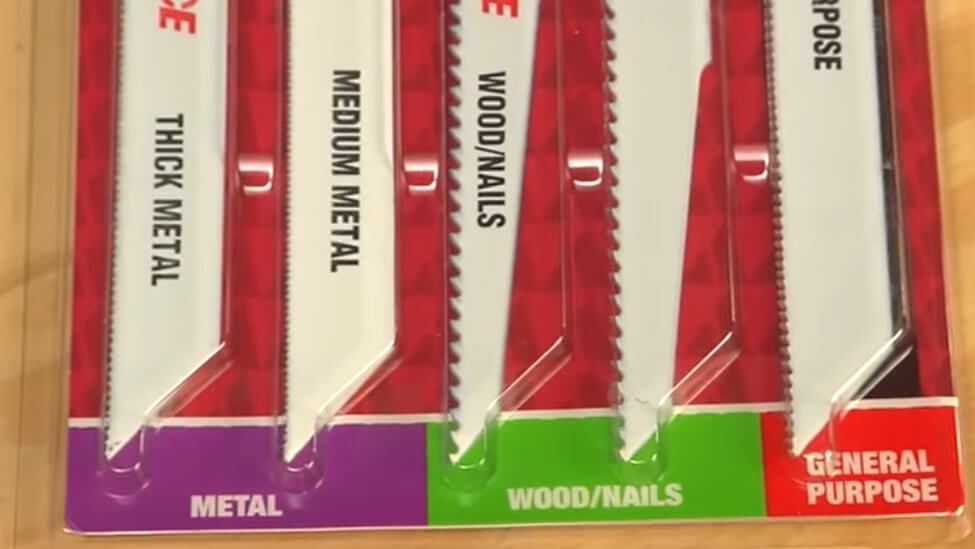

Different Types Of Reciprocating Saw Blades And When To Use Them

Reciprocating saw blades come in several types, each designed for specific materials and tasks. Some of the common types of reciprocating saw blades are:

- Wood blades: These are designed for cutting through wood and tree branches.

- Metal blades: These are used for cutting through metal pipes, rods, and sheets.

- Demolition blades: These are ideal for heavy-duty tasks such as cutting through drywall, plaster, and nails.

- Pruning blades: These blades are used for trimming trees and shrubbery.

When choosing a reciprocating saw blade, you should consider the material you will be cutting and the thickness of that material.

- For wood cutting, choose a blade with fewer teeth per inch (TPI).

- For metal cutting, select a blade with more TPI.

- For demolition, select a blade with carbide teeth for increased durability.

- For pruning, pick a blade with offset teeth that will cut through the wood without getting caught.

Advantages Of A Reciprocating Saw Over Other Cutting Tools

Reciprocating saws offer several advantages over other cutting tools. Here are a few:

- Versatile: A reciprocating saw can cut through a range of materials, making it a versatile tool for different projects.

- Precision cutting: With its back-and-forth motion, a reciprocating saw allows for more precise cutting than other cutting tools.

- Accessibility: The shape of a reciprocating saw makes it easy to cut in tight or hard-to-reach places.

- Maneuverability: The handle of a reciprocating saw offers a comfortable grip, making it easy to control and maneuver during cutting.

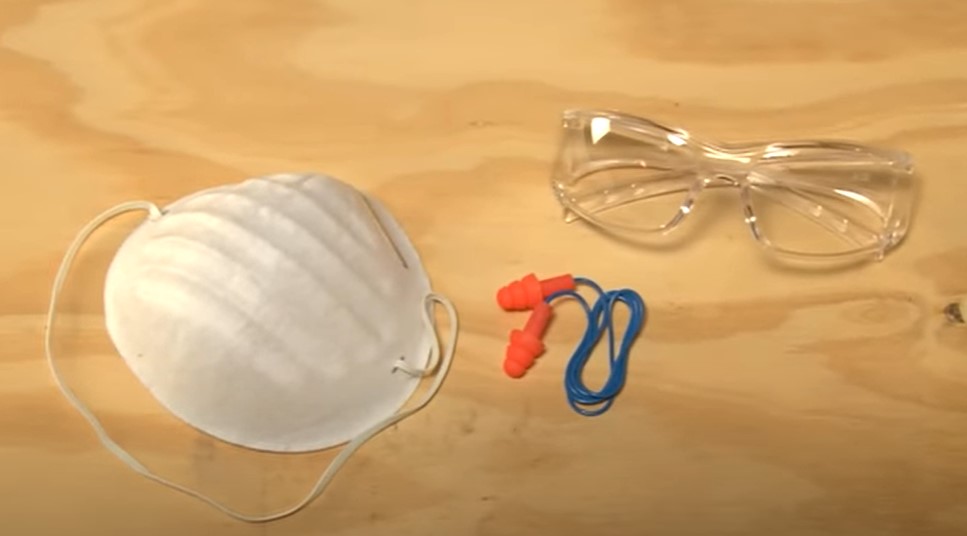

If you want to make precise cuts quickly and easily, a reciprocating saw is an excellent tool to invest in. Just remember to choose the right blade for the job and use the appropriate safety gear, such as gloves and eye goggles.

Preparing For The Straight Cut

Proper preparation is essential before beginning the cutting process with a reciprocating saw. Understanding the types of materials that can be cut using this tool is crucial in selecting the appropriate blade for the job.

Safety precautions should also be considered before using the tool, including wearing personal protective equipment and ensuring the work area is clear of any potential hazards. Properly setting up the material for the cut is equally important, ensuring it is securely clamped or held in place to prevent any movement during the cutting process.

To improve comprehension, let’s examine the specifics of each point listed below.

Types Of Materials That Can Be Cut Using A Reciprocating Saw

Reciprocating saws are versatile power tools that are ideal for cutting various materials. From wood to metal, these saws can cut through it all. Here are some of the materials that can be cut using a reciprocating saw:

- Wood: The reciprocating saw’s aggressive tooth pattern makes it a perfect tool for cutting through different types of wood, including lumber, plywood, and hardwood.

- Metal: Reciprocating saws equipped with a bi-metal blade can cut through a wide range of metals, such as steel pipes and aluminum sheets.

- Pipes: These saws can accommodate various pipe-cutting tasks, including cutting plastic, copper, and PVC pipes.

- Drywall: With the right blade, a reciprocating saw can cut through drywall like a breeze.

- Nails and screws: Reciprocating saws equipped with metal cutting blades can cut through screws and nails during demolition or remodeling projects.

Safety Precautions To Consider Before Using The Tool

As with any power tool, safety should be your top priority when using a reciprocating saw. Here are some safety precautions to consider before using the tool:

- Wear protective gear: Always wear safety goggles, ear protection, gloves, and a dust mask to protect yourself from flying debris, loud noise, and dust.

- Inspect the saw: Before using the saw, inspect the blade, blade clamp, and the body of the tool for any damage or defects.

- Secure the workpiece: Make sure the workpiece is firmly secured using a clamp or a vise before you begin cutting to prevent the piece from shifting during the cut.

- Avoid cutting into walls: Be cautious when using a reciprocating saw in walls, as electrical wires and pipes are often hidden behind the drywall.

- Avoid touching the blade: Never touch the blade or try to change it while the saw is plugged in.

- Unplug the saw when not in use: Remember to unplug the saw when not in use, and keep it out of the reach of children.

How To Properly Set Up The Material For The Cut

Properly setting up the material for the cut is vital to ensure that you make a clean and accurate cut. Here are the steps to properly set up the material:

- Measure and mark the cut: Measure and mark the material accurately using a ruler, a pencil, and a square to ensure that you cut at the correct location.

- Secure the material: Before you begin cutting, ensure that the material is firmly clamped down to prevent it from moving during the cut.

- Choose the right blade: Choose the right blade based on the type of material you are cutting, and select the proper blade length for the thickness of the material.

- Select the right speed: Choose the right speed setting on your reciprocating saw to ensure enough power for the cut. Lower speeds work better for delicate materials, while higher speeds suit thicker and tougher materials.

- Start cutting: Hold the saw firmly with both hands and slowly begin to cut. Follow the marked line closely, and ensure that the blade does not twist or bend while cutting.

Techniques For Cutting Straight

Using a reciprocating saw is an efficient way to cut through many materials, including wood and metal. However, cutting straight with this tool can be challenging, particularly for inexperienced users. Here are some techniques you can use to cut straight with a reciprocating saw.

Proper Stance And Grip When Using The Tool

Having the right stance and grip can help you cut straight with a reciprocating saw. Here are some tips for correct stance and grip:

- Stand with your feet shoulder-width apart and face the cutting direction.

- Hold the saw with both hands, placing one hand on the handle and the other on the blade guard.

- Use a firm grip but not too tight. Over-gripping can cause fatigue and even prevent you from controlling the saw.

Marking The Cut Line Before Beginning

Marking the cut line is an essential step in cutting straight with a reciprocating saw.

Here is why:

- It helps you maintain the right direction while cutting.

- It ensures that you cut the right size and shape of the material.

- It reduces the chances of mistakes and wasting material.

Keep The Saw Straight During The Cut

Keeping the saw straight is crucial to achieving a straight cut. As reciprocating saws make a substantial vibration during cuts, it is difficult to keep them in line. However, you can follow the following methods to keep it in a straight line during the cut:

- You can use a guide, such as a straight edge, to guide the saw during the cut.

- Keep your eyes on the blade and the cut line at all times.

- Apply even pressure on the saw while cutting.

- Avoid overcorrecting if you notice the saw starting to veer off course. Instead, adjust the direction slowly and gradually.

With these techniques, even beginner DIYers can cut straight with a reciprocating saw. However, always remember to prioritize safety while working with power tools.

Common Mistakes To Avoid

The Most Common Mistakes People Make When Cutting With A Reciprocating Saw

When it comes to using a reciprocating saw for cutting, there are a few common mistakes that people make. Here is an overview of these mistakes:

- Improper blade selection – using the wrong blade for the job can lead to inaccurate cuts and reduced safety.

- Incorrect blade installation – installing the blade incorrectly can also lead to inaccurate and potentially dangerous cuts.

- Inconsistent pressure – applying inconsistent pressure can lead to uneven cuts, jagged edges, and dangerous kickbacks.

- Poor positioning – failing to keep the saw in the appropriate position throughout the cut can also lead to jagged and inaccurate cuts.

The Impact Of These Mistakes On The Cut’s Accuracy And Safety

It’s essential to avoid these common mistakes because they can have significant impacts on the cut’s accuracy and safety. Here are some potential impacts:

- Inaccurate and uneven cuts – using the wrong blade, installing it incorrectly, or applying inconsistent pressure can all result in less accurate cuts with uneven edges. This can be a problem if you need a clean, straight cut for your project.

- Dangerous kickback – applying too much pressure or using an incorrect blade can lead to a dangerous kickback, which can cause serious injury. Kickback occurs when the blade grips the material too aggressively, causing the saw to jump back toward the operator.

- Longer project completion time – if you have to redo cuts or spend extra time fixing mistakes, your project completion time may be longer than anticipated.

Tips For Avoiding And Correcting These Mistakes

Here are some tips for avoiding and correcting the common mistakes when cutting with a reciprocating saw:

- Use the correct blade – always make sure to choose the right blade for the job at hand. This will allow you to make clean, accurate cuts and reduce the risk of kickback.

- Install the blade correctly – double-check that you have installed the blade correctly before starting your cut. Follow the manufacturer’s instructions and ensure the blade is firmly in place.

- Apply consistent pressure – try to apply consistent pressure throughout the entire cut. This will help you achieve a straight cut with a smooth finish.

- Maintain proper positioning – keep the saw in the appropriate position throughout the cut. This will help you achieve an accurate cut without jagged edges.

By avoiding these common mistakes and following the tips provided, you can use a reciprocating saw to make clean, accurate cuts safely and efficiently.

Fine-Tuning The Cut

Techniques For Making A Perfectly Straight Cut With A Reciprocating Saw

If you’re working with a reciprocating saw and aiming for perfectly straight cuts, here are some techniques to help you achieve your goal:

- For shorter cuts, marking the cut line with a sharpie or a pencil will help guide you in making a straight cut.

- Using a straight edge will guide your tool, allowing you to make a straight cut. Clamping the edge in place before cutting will provide better accuracy.

- If you’re making a long cut, using a chalk line or a laser level can help you visualize the cut line, making it easier to maintain a straight cut.

Equipment And Tools That Can Be Used To Refine The Cut

Sometimes, the tools you’re using may not be enough to achieve the level of precision you want. In such cases, the following tools and equipment can be used to refine your cut:

- Reciprocating saw guides can be used to achieve a straight cut. These attach to the saw and help guide the saw along your cut line.

- A laser guide, which projects a beam onto your material, allows the operator to make adjustments as needed to maintain a straight cut in real time.

- Changing the blade can help achieve a finer cut with a reciprocating saw. Coarser blades are designed to move through the materials more quickly, leading to a rougher cut, while finer blades move more slowly and precisely.

Correcting Any Deviations Or Mistakes Made During The Cut

Not all cuts go according to plan, and when mistakes happen, it’s important to know how to correct them. Here are some tips for correcting any deviations or mistakes made during the cut:

- If you’ve accidentally veered away from your cutting line, stop cutting and reassess before continuing. Make sure the material you’re cutting is secure and that it hasn’t moved out of position before realigning the saw to the proper cutting angle.

- Sandpaper and files can be used to smooth out rough cuts or to refine your cut. Depending on the material you’re working with, different grits of sandpaper may be required.

- If the cut is too rough and beyond repair, it’s best to cut a new piece and start over. Remember to take your time and use the proper cutting techniques to achieve a straight, clean cut.

FAQs: How To Cut Straight With A Reciprocating Saw?

How Do I Cut Straight With A Reciprocating Saw?

To cut straight with a reciprocating saw, start slowly and follow a guide or a straight line. It is also better to use a blade that is longer than the object you are cutting.

What Is The Best Blade For Cutting Straight Lines?

The best blade for cutting straight lines is the one with fewer teeth per inch. This blade will cut faster and provide a cleaner finish on the cut.

Can I Change The Blade Of My Reciprocating Saw?

Yes, you can change the blade of your reciprocating saw by following the manufacturer’s instructions. Always make sure the saw is unplugged or the battery is removed before changing the blade.

What Is The Maximum Thickness A Reciprocating Saw Can Cut?

Reciprocating saws can easily cut through materials up to 6 inches thick depending on the blade and the type of material. Ensure the blade is appropriate for the thickness of the material you are cutting.

How Do I Prevent My Saw From Overheating?

To prevent your saw from overheating, give it a break periodically and let the blade cool down. Use a blade that is suitable for the material you are cutting and do not overload the saw by cutting materials that are too thick.

Conclusion

Mastering the art of using a reciprocating saw can save you time and effort in many DIY projects. While cutting straight with a reciprocating saw may seem daunting, the techniques and tips discussed in this post can help you achieve a smooth and accurate cut.

Always remember to wear protective gear, choose the right blade for the material you are cutting, and keep a firm grip on your tool. With the proper precautions and steady techniques, your projects will come out looking professional and polished.

Practice is key, so don’t get discouraged by any mistakes. Keep practicing and honing your skills, and soon you’ll find that the reciprocating saw is a versatile and valuable tool to have in your DIY arsenal. Happy cutting!

Recent Posts

Woodworking in 2025 is all about efficiency, precision, and smart technology. Whether you're a beginner or a seasoned craftsman, having the right tools can make all the difference. Here are the top 7...

Ever tried drilling into a piece of wood only to end up with a splintered mess or a wobbly hole? Yeah, it's more common than you think. Wood might seem like an easy material to work with, but...