Circular saw blades are typically hardened. This process ensures they are durable and long-lasting.

Circular saw blades are a crucial tool for any woodworker or contractor. They are specifically designed to cut through materials like wood, metal, plastic, and other materials with precision and ease. To ensure that these tools are as effective as possible, they must be made with high-quality materials and undergo a hardening process.

Are Circular Saw Blades Hardened? Reveal The Truth

Yes, circular saw blades can be hardened. Hardening is a process where the blade undergoes heat treatment, such as annealing, tempering, or quenching, to increase its hardness and durability.

This hardened state allows the blade to withstand the rigors of cutting through various materials, resulting in improved performance and longevity.

By selecting hardened circular saw blades, woodworkers can achieve more precise cuts and reduce the need for frequent blade replacements.

What Does It Mean For A Circular Saw Blade To Be Hardened?

Circular saw blades are one of the most common tools used in various cutting applications. One of the most fascinating things about a saw blade is the hardening process it undergoes before it can serve its purpose.

The hardening process is a heat treatment method that makes the saw blade significantly harder than its original form.

In this section, we will look at what it means to harden a saw blade and why it is essential. We will also delve into the different types of hardening methods used in making saw blades.

Explanation Of The Hardening Process

The hardening process is a crucial step in making a saw blade. It involves heating the blade to a particular temperature and then cooling it rapidly through quenching. This process alters the molecular structure of the steel blade, hardening it, and making it more durable and longer-lasting.

The quenching process results in a reduced blade thickness, making it sharper and enabling it to cut through tough materials with ease.

Why Hardening Is Important For Saw Blades?

Hardening is essential in the production of saw blades for various reasons.

Firstly, it enhances the durability and longevity of the blade, ensuring that it lasts longer and saves the user money in the long run.

Secondly, it makes the blade stronger, allowing it to cut through dense materials, reduce vibration during cutting, and maintain its sharpness.

Finally, it makes the blade more resistant to wear and tear and protects it from damage, guaranteeing that it can withstand tough cutting conditions.

Types Of Hardening Methods Used For Saw Blades

Several methods are used to harden saw blades, depending on the type of material and the desired blade functionality.

We’ve listed the most common ones below:

Induction hardening: This type of hardening uses an electrical current to create a magnetic field that heats the blade surface to a specific temperature before it is quenched.

Flame hardening: This process involves heating the blade using a flame and then quenching it in water or oil.

Salt bath hardening: This method involves immersing the blade in a salt bath before heating it to high temperatures and then quickly quenching it.

Cryogenic hardening: This process uses very low temperatures to alter the steel’s internal structure, making the saw blade more durable.

Hardening is a crucial step in making saw blades. It improves their durability, strength, and resistance to wear and tear.

Different methods of hardening can be used, depending on the desired blade functionality, and we hope you have learned something new about this fascinating process.

Techniques For Hardening Circular Saw Blades

Heat treatment is a common technique used to harden circular saw blades. It involves subjecting the blade to controlled heating and cooling processes.

The three primary heat treatment techniques are:

a. Annealing: This process involves heating the blade to a specific temperature and then slowly cooling it. Annealing helps reduce internal stresses in the blade and enhances its overall hardness.

b. Tempering: Tempering is performed after the blade has been hardened to make it less brittle. The blade is heated to a specific temperature and then cooled rapidly. This process increases the blade’s toughness and reduces the risk of fracture.

c. Quenching: Quenching is a rapid cooling process that follows the initial heating of the blade. It involves immersing the hot blade in a quenching medium, such as oil or water, to quickly cool it down. Quenching increases the hardness of the blade’s cutting edge, making it more suitable for demanding cutting tasks.

These techniques ensure that circular saw blades are hardened to withstand the demands of various cutting applications, resulting in improved cutting performance, durability, and longevity.

How Are Circular Saw Blades Made?

Circular saw blades are made using a process called blanking, where large coils of steel are cut into circular discs. The discs are then heated and softened, making them easier to shape.

The blades are then stamped out, and the holes for the saw teeth are drilled.

Once the teeth are attached, the blade is sharpened and hardened using a heat treatment process.

Materials Used To Make Saw Blades

The most common material used for saw blades is a type of steel known as high-speed steel (HSS). This steel contains a combination of tungsten, molybdenum, and cobalt, making it incredibly hard and durable.

Another material commonly used for saw blades is carbide-tipped steel.

This material combines a steel body with a carbide tip to produce a blade that is even more durable and can cut through even the toughest materials.

Here are some commonly used materials in making circular saw blades:

High-speed steel (HSS): Hss blades are made from a mix of carbon, tungsten, and high-speed steel, making them tougher and last longer than regular blades. They are suitable for cutting wood, plastic, and non-ferrous metals.

Carbide-tipped blades: Carbide tips are brazed onto the saw blade’s teeth, making them ideal for cutting hardwoods, composite materials, and even metal. They are more expensive than regular blades but last longer.

Diamond-tipped blades: Diamond-tipped blades are designed to cut through abrasive materials such as concrete, tiles, and masonry. The blades have industrial diamonds attached to the teeth, giving them superior cutting ability.

Stellite-Tipped Blades: Stellite-tipped blades are another type of hardened circular saw blade. Stellite is a cobalt-based alloy known for its exceptional hardness, wear resistance, and heat resistance.

Blades with Stellite tips are often used for cutting abrasive materials, such as fiberglass, composite materials, and certain metals. The Stellite tips provide excellent cutting performance and maintain their sharpness for extended periods.

Different Types Of Saw Blades And Their Uses

There are several different types of saw blades available, each designed for a specific cutting application. Here are a few of the most common types of saw blades and their uses:

Rip blades: These blades are designed to cut with the grain of wood and are used for making long, straight cuts. They have fewer teeth and larger gullets that allow them to clear the sawdust faster.

Crosscut blades: These blades are used for cutting across the grain of wood and produce a smoother cut than rip blades. They usually have a higher number of teeth and smaller gullets to provide cleaner cuts.

Combination blades: These blades are designed to be versatile and can be used for both ripping and crosscutting. These saw blades tend to have 24-40 teeth, making them suitable for most woodworking projects.

Plywood blades: These blades have more teeth than other types of blades and are specifically designed for cutting through plywood and other laminates.

Fine-tooth blades: These blades are used for making precision cuts in thin materials such as sheet metal or plastic.

Dado blades: Dado blades are used to make precise cuts in woodworking projects where grooves need to be of a specific width. They have two blades that are adjustable and can be set to a specific width.

Circular saw blades are an essential tool for any workshop or DIY project. Understanding how they are made and the different types available will help you choose the right blade for your specific cutting needs.

Factors Affecting Blade Hardness

Circular saw blades are the cutting tools that make woodworking fast and convenient. One factor that affects the functionality and effectiveness of saw blades is their hardness. In this blog post, we will explore the importance of blade hardness in sawing applications, the factors that impact blade hardness, and industry standards for blade hardness.

Importance Of Blade Hardness In Sawing Applications

The hardness of a saw blade may seem like a trivial factor; however, it plays a crucial role in the cutting operation. Here are some reasons why:

Blade Durability: Hardness determines how long a saw blade will last. A harder blade will stay sharp longer than a softer one, which means that it will last longer.

Cuts clean and straight: A harder blade is less likely to deflect and bounce off the workpiece. That means it will produce clean and straight cuts, which is crucial for achieving the desired results.

Resists wear and tear: Cutting different woods and materials with a saw blade can cause wear and tear on its teeth. A harder blade is more resistant to wear and tear, which is essential for making precise cuts over time.

Factors That Impact Blade Hardness

Several factors impact blade hardness, including the following:

Type of material: Different materials have varying levels of hardness and saw blades made for softer materials tend to be less hard than those made for harder ones.

Heat treatment: Saw blades go through a heat treatment process to attain their hardness levels. The faster they cool down, the harder they become.

Composition of the blade: The composition of the blade, such as the type of steel or carbide that it’s made of, can affect blade hardness.

Industry Standards For Blade Hardness

Fortunately, the industry has established standards for blade hardness. The Rockwell scale is the most commonly used measure of saw blade hardness. The hardness of the blade is expressed as HRC followed by a number, with higher numbers indicating harder blades.

The Rockwell hardness number can vary depending on the type of blade and the material it cuts. A typical range for circular saw blades is 45-65 HRC.

To wrap up this guide, remember that the hardness of a circular saw blade is a crucial factor in achieving clean and precise cuts. Different factors affect blade hardness, including the material type, heat treatment, and blade composition.

Finally, learn more about Rockwell hardness number standards, which are essential in ensuring that the saw blade’s hardness is up to the industry’s requirements.

Benefits Of Using Hardened Circular Saw Blades

Circular saw blades are a critical tool in any woodworker’s arsenal, making precise cuts with ease.

But, not all saw blades are made equal. Some are hardened, while others aren’t, and this can significantly impact performance, durability, and safety.

Here, we will focus on the benefits of using a hardened saw blade.

Improved Performance And Durability

Hardened saw blades undergo a thermal treatment process that significantly improves their performance. During the hardening process, the steel is heated and cooled rapidly, increasing its strength and durability. As a result, these blades can make cleaner cuts, with less effort, and in less time.

The hardening process also makes the blade less prone to wear and tear, which improves its lifespan and reduces the costs of replacing it.

- Hardened saw blades undergo a thermal treatment process to improve their performance

- The process increases the blade’s strength, durability, and ability to make cleaner cuts.

- Reduced wear and tear enhances the blade’s lifespan and reduces the costs of replacing it.

Extended Blade Life And Reduced Costs

Circular saw blades are expensive, and having to replace them frequently can quickly add up. However, by using a hardened saw blade, you can extend the life of the blade. A hardened saw blade is far more durable than a non-hardened one, and therefore, it will maintain its sharpness for longer periods of time.

This means that the blade won’t need to be sharpened as frequently, and the need for replacement is pushed further out.

Ultimately, these savings add up, making it a more cost-effective option in the long run.

- Using a hardened saw blade will extend the life of the blade

- The blade is more durable and maintains its sharpness longer, compared to a non-hardened blade

- The need for sharpening the blade or replacing it reduces, which is more cost-effective in the long run.

Enhanced Safety And Reduced Risk Of Accidents

Another significant benefit of using a hardened saw blade is enhanced safety and reduced risks of accidents. Non-hardened blades tend to wear out over time, leading to bluntness, and when the blade becomes blunt, it can lead to kickbacks, which can cause serious accidents.

On the other hand, a hardened saw blade maintains its strength, sharpness, and durability, and the risks of accidents are significantly reduced.

- Using a hardened saw blade enhances safety and reduces accidents

- Non-hardened blades tend to become blunt and cause kickbacks, leading to accidents

- A hardened saw blade maintains its strength, sharpness, and durability, significantly reducing accident risks.

Using a hardened saw blade is an excellent investment for any woodworker. Improved performance, durability, extended blade life, reduced costs, and enhanced safety are all benefits you can gain from using a hardened saw blade.

Therefore, it is essential to consider this factor the next time you’re in the market for a saw blade.

How To Identify Hardened Saw Blades?

Circular saw blades are a critical tool for carpenters and DIY enthusiasts alike. An essential consideration for any craftsman is whether the saw blade they are using is hardened or not.

Hardened saw blades are perfect for precision cutting and have long-lasting durability because they don’t dull as quickly as non-hardened blades.

Here, we’ll discuss how to identify hardened saw blades.

Differentiation Between Hardened And Non-Hardened Blades

Differentiating between hardened and non-hardened saw blades is necessary before considering other methods of identification.

While this may sound simple, there are a few things to note when distinguishing between these two types of blades.

Non-hardened blades are typically thin, flexible, and susceptible to bending.

Conversely, hardened saw blades are thicker, sturdier, and more difficult to bend.

Visual And Hardness Test Identification Methods

Once you have determined that the saw blade is hardened, it’s time to identify it correctly.

There are two primary ways to do this, visual identification and hardness testing.

When carrying out visual identification, you should look out for the following features:

- Labeled as “hardened.”

- Visible dark blue to black color.

- No chips or dull spots.

Hardness testing can also be used to identify hardened saw blades. A “Rockwell hardness test” is one such test that measures the blade’s hardness by determining the amount of pressure it can withstand.

Manufacturers use this test to rate blades from a hardness perspective, and it’s typically expressed as a Rockwell hardness number.

Tips And Tricks For Assessing Blade Hardness In The Field

While looking for visible signs or carrying out hardness testing, there are some tips and tricks to help you assess blade hardness in the field easily. Consider the following:

Drop the blade on the ground from a distance of about 6 inches. If the blade rings or hums, it is hardened.

Test the blade’s flexibility by bending it slightly. If it’s challenging to bend, it’s hardened.

Look out for any visible chips or dull spots on the blade. The absence of these usually indicates that the blade is hardened.

It’s critical to ensure that you use a hardened saw blade for precision cutting and long-lasting durability. Differentiate between hardened and non-hardened blades, perform visual and hardness testing, and assess blade hardness in the field to ensure that you have the right tool for the job.

Choosing The Right Hardened Circular Saw Blade

The selection of the right blade for a specific task is critical to the success of the project. Here are some factors you need to consider when choosing the right blade:

The type of saw: Different blades are suitable for different saws, including cordless circular saws, table saws, and miter saws.

Blade diameter: The blade diameter determines how deep the saw can cut. The larger the blade diameter, the deeper the cut.

Tooth configuration: The tooth configuration will determine the quality of the cut and the speed of cutting. Blades with more teeth are more suitable for cross-cutting, while blades with fewer teeth are suited for ripping.

The material being cut: Different blades have different tooth configurations and are designed to cut specific materials. Selecting the right blade for the material you’re cutting will ensure the best results.

Selecting the right circular saw blade is essential for achieving desired cutting results. Understanding the different types, construction and material variations, and blade selection and application can help you choose the right circular saw blade for your project.

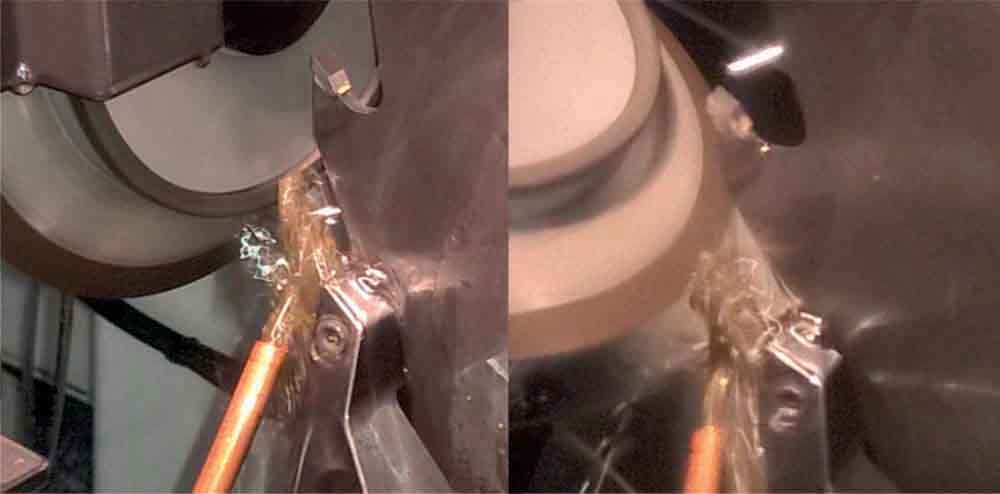

Can You Harden A Circular Saw Blade [Video]

Maintenance And Care For Hardened Circular Saw Blades

To ensure the longevity and performance of your hardened circular saw blades, it is important to implement proper maintenance and care practices.

Proper storage practices:

Proper storage practices involve storing the blades in a dry, cool area, away from direct sunlight and moisture. It is also recommended to use blade covers or sheaths to protect the teeth and edges from damage during storage.

Cleaning and sharpening techniques:

Cleaning and sharpening techniques should be done with precision and attention to detail. Using a cleaning solution and soft cloth to remove any debris or residue from the blades is essential to keep them in optimal condition.

Sharpening should be done with professional-grade tools and techniques to avoid damage to the teeth and ensure a clean and precise cut.

By following these practices, you can extend the life and performance of your hardened circular saw blades.

Safety Considerations

When it comes to working with hardened circular saw blades, there are a number of safety considerations that must be taken into account. These are:

Handling hardened blades: It is essential to handle these blades with the utmost care, as they are extremely sharp and can cause serious injury if mishandled.

This means wearing protective gloves and using appropriate tools to change blades.

Eye and ear protection: It is also crucial to protect your eyes and ears when using these blades.

Eye protection should be worn at all times to prevent debris from flying into your eyes, while ear protection will help reduce the risk of hearing damage caused by the loud noise these blades can produce.

By following these safety considerations, you can help to ensure that you and your colleagues remain safe when working with hardened circular saw blades.

Frequently Asked Questions Of Are Circular Saw Blades Hardened

Are Circular Saw Blades Hardened?

Yes, circular saw blades are hardened to increase their durability and extend their lifespan.

What Are Circular Saw Blades Made Of?

Circular saw blades are typically made of high-grade steel or carbide-tipped with varying thicknesses.

What Is The Lifespan Of A Circular Saw Blade?

The lifespan of a circular saw blade depends on the frequency of use, the materials it cuts, and the quality of the blade.

Can You Sharpen Circular Saw Blades?

Yes, circular saw blades can be sharpened, but it is often more cost-effective to replace them.

What Is The Difference Between Steel And Carbide-Tipped Saw Blades?

Steel blades are cheaper, while carbide-tipped blades are more expensive but last longer and are more effective at cutting harder materials.

How Do I Choose The Right Circular Saw Blade?

Choose a blade based on the materials you will be cutting and the saw’s rpm rating and diameter requirements.

Conclusion

Circular saw blades are essential tools for achieving precision and accuracy in woodworking projects. Professionals and hobbyists alike require top-notch quality blades for hassle-free and accurate cuts. While the process of hardening circular saw blades has been adopted widely, not all blades are hardened.

This blog post aimed to answer this critical question – are circular saw blades hardened? From our extensive research, we can conclude that circular saw blades can either be hardened or not depending on the intended use and the manufacturer’s preference.

It is vital to select the appropriate blade type that suits the desired cutting task. Before choosing a circular saw blade, it’s important to consider the material, teeth count, and blade type.

We recommend investing in high-quality, hardened circular saw blades to achieve exceptional results, prevent wear and tear, and extend the blade usage life.

Choose wisely and achieve supreme-cutting results!

Related Post:

What are 5 Uses For A Circular Saw?

How To Sharpen Your Circular Saw Blade With A File?

How Many Watts Does A Circular Saw Use?

Miter Saw Vs Circular Saw: Which Is The Most Useful

Recent Posts

Woodworking in 2025 is all about efficiency, precision, and smart technology. Whether you're a beginner or a seasoned craftsman, having the right tools can make all the difference. Here are the top 7...

Ever tried drilling into a piece of wood only to end up with a splintered mess or a wobbly hole? Yeah, it's more common than you think. Wood might seem like an easy material to work with, but...