Looking to cut through anything like butter? Look no further than a trusty circular saw! But what happens when your saw starts losing its edge? Don’t let frustration get the best of you! The answer is simple: sharpen your circular saw blade!

Trust us, it’s easier than it sounds. Just grab a file and follow our expert tips, and you’ll have that saw slicing through wood and metal like a hot knife through butter in no time.

Sharpen like a pro and show that saw who’s boss!

The concept of sharpening tools, including saw blades, dates back thousands of years. Ancient civilizations used various methods like whetstones and primitive files to maintain the sharpness of their cutting implements.

Why Is It Important To Maintain Your Circular Saw Blades Sharp?

Maintaining sharp circular saw blades is crucial for efficient and safe cutting. Dull blades not only slow down the cutting process but also increase the risk of kickbacks and other accidents.

A dull blade can cause the saw to overheat, which can lead to warping or even breakage of the blade. Additionally, a dull blade can cause jagged cuts that not only look unprofessional but can also compromise the integrity of the material being cut.

To keep circular saw blades sharp, it is important to regularly inspect them for damage or wear and tear. The sharpening process typically involves using a saw file or diamond-tipped file to remove any burrs or nicks from the blade’s teeth.

It is important to maintain the correct angle and depth of the teeth during sharpening to ensure optimal cutting performance.

Additionally, it is recommended to have blades professionally sharpened at least once a year for optimal results.

By regularly maintaining and sharpening circular saw blades, users can ensure safety and efficiency in their cutting tasks.

Understanding The Types Of Circular Saw Blades:

Circular saw blades are essential tools for cutting through various materials with precision and efficiency. There are different types of circular saw blades that are designed for specific cutting tasks.

The three main types of circular saw blades are:

- Rip-cut blades,

- Crosscut blades, and

- Combination blades.

Rip-cut blades feature fewer teeth with large gaps between them, making them ideal for cutting along the grain of wood. They are ideal for the efficient removal of wood for long straight cuts.

For instance, a 24-tooth rip-cut blade can efficiently cut through thick hardwoods.

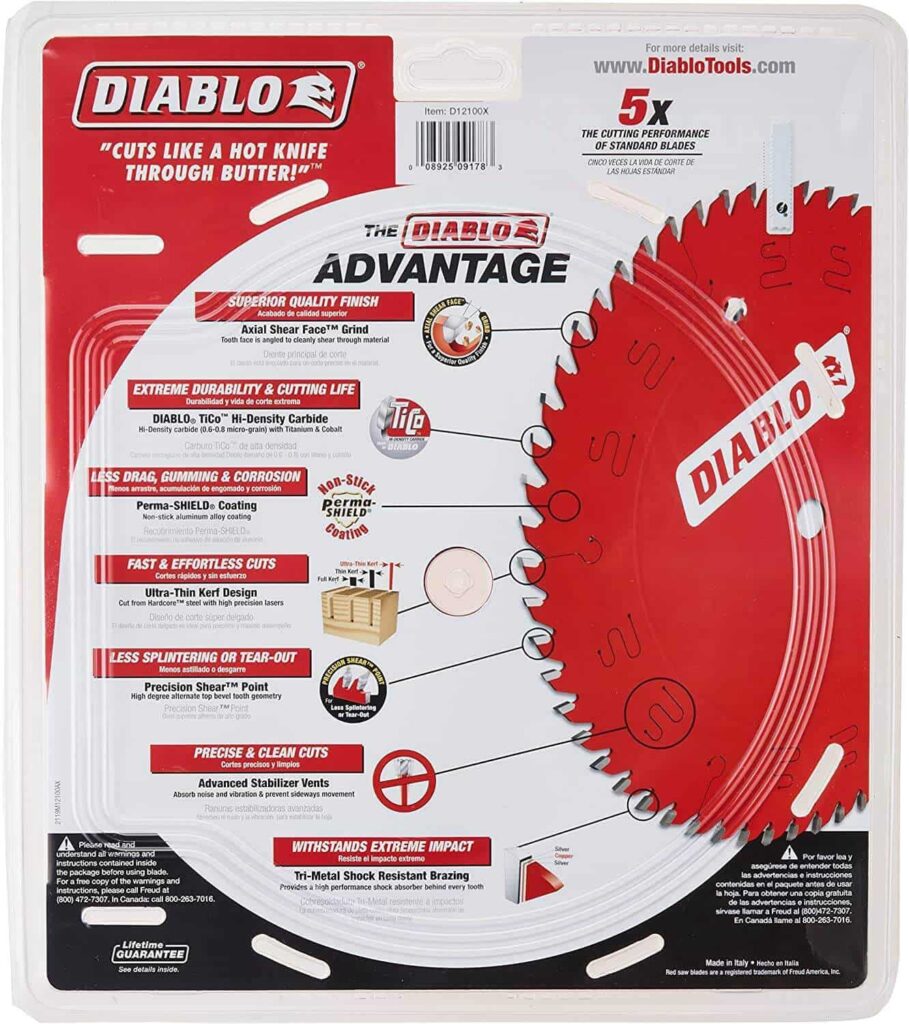

An example of a rip-cut blade is the Freud D12100X Diablo. You will find laser-cut stabilizer vents in these blades which can trap noise and vibration and stabilize the blade while cutting.

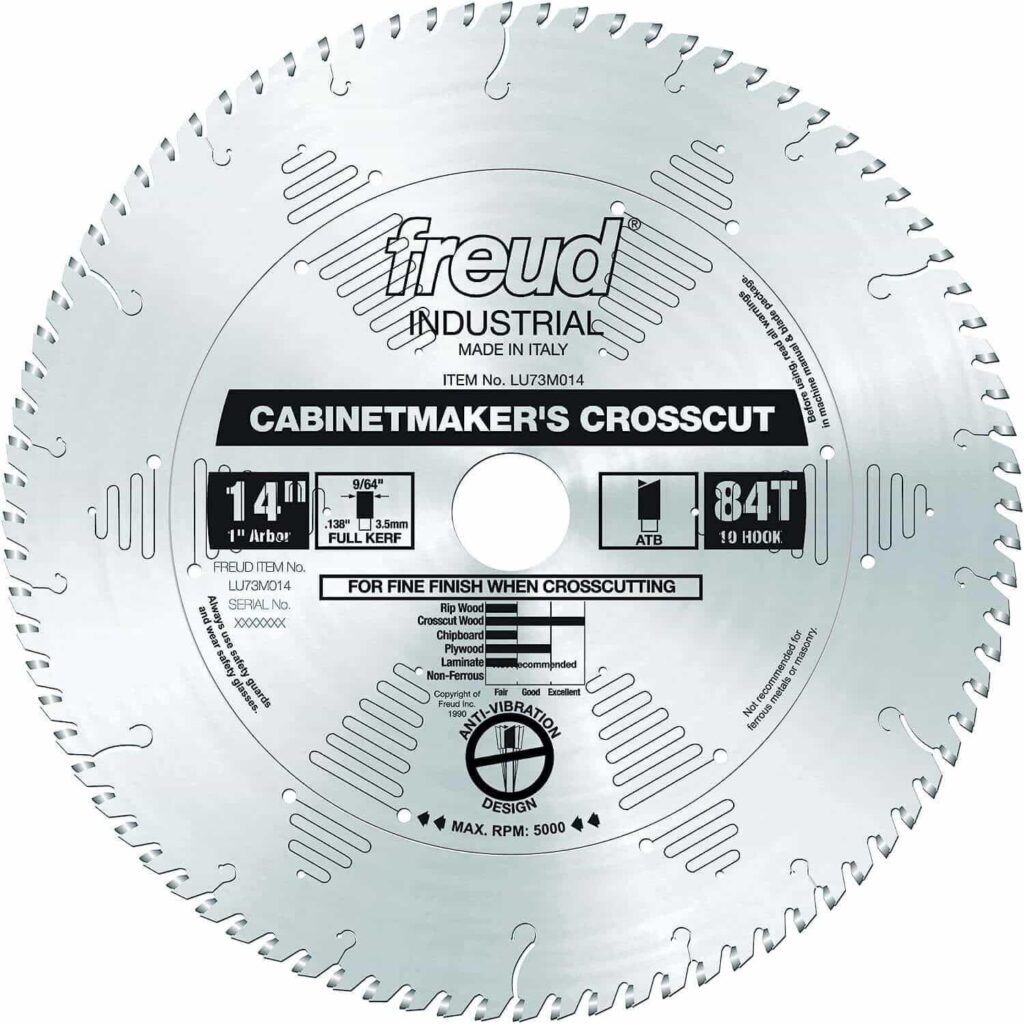

Crosscut blades, on the other hand, have more teeth set in a tight pattern, making them perfect for cutting across the grain.

Crosscut blades are preferable when you need precision cut with a smoother finish. A 60-tooth crosscut blade can effectively cut through softwoods and plywood.

The Freud LU72R014 crosscut blade is an excellent example of a crosscut blade. These blades are made of a premium TiCo HI-density carbide crosscutting blend for ultimate precision and max performance.

Finally, combination blades are designed to perform both rip and crosscut tasks, making them versatile and efficient for various cutting applications. You can get a perfect general-purpose cutting with a 50-tooth combination blade within moments.

The DEWALT DW3325 is a popular example of a combination blade. This 7 1/4-inch blade constructed of fully hardened steel can cut straight, rip, or crosscut through many types of wood.

Choosing the right type of circular saw blade for a specific project is crucial to achieving accurate and efficient results.

What Are The Components Of A Circular Saw Blade?

A circular saw blade is a vital tool for cutting through various materials, from wood to steel. Therefore, it is crucial to understand its components to ensure that it performs optimally.

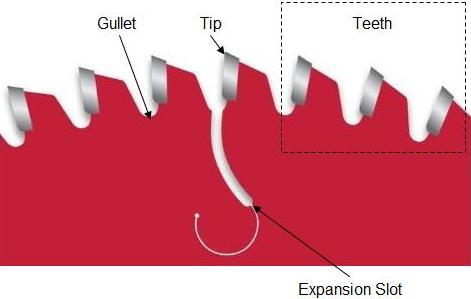

The main components of circular saw blades are-

- Teeth

- Gullet

- Kerf

- Plate

- Arbor hole

Here, the teeth are the sharp, angled edges that cut into the material. They come in different configurations, such as rip and crosscut, and the number of teeth affects the blade’s speed and smoothness of the cut.

- The gullet is the space between teeth and helps remove chips and debris from the cut.

- The kerf is the width of the cut, determined by the blade’s thickness.

- The plate is the body of the blade that supports the teeth and determines the blade’s overall durability.

- The arbor hole is the center hole that fits onto the saw’s spindle for rotation.

Understanding these components is essential in choosing the right blade for the job.

What Are The Signs Of A Dull Circular Saw Blades?

Whether you are a professional or a DIY enthusiast, you must be aware of the indications that suggest a circular saw blade has become dull. Reduced cutting efficiency, scorch marks on the wood, and increased force required to make cuts are a few of the signals that serve as a reminder that the blade needs to be sharpened.

- Poor cutting performance is often a clear indication that the blade needs to be replaced. If the blade is struggling to make clean cuts, producing rough or jagged edges, it may be time for a new blade.

- Burn marks on the wood are another indicator of a dull blade. If the blade heats up and burns the wood during the cutting process, it is likely that the blade is no longer sharp enough.

- Finally, if cutting requires increased effort and the saw feels like it’s struggling, it’s time to consider replacing the blade.

Regularly checking and maintaining your saw blades will ensure optimal performance and a safer working environment.

Expert Tips On How To Sharpen Your Circular Saw Blade

If you want to sharpen a circular saw blade using a file, it is essential to follow the correct steps to achieve the best results. Your safety is paramount, so before starting, make sure you securely clamp the blade in place. It is recommended to use a file that matches the size of the blade’s teeth.

It is crucial to remember that you should only file the cutting edge of the teeth at a consistent angle throughout the process. Overfilling or removing too much of the blade’s material should be avoided.

Remember that only a correctly sharpened saw blade will perform at its best and provide clean, accurate cuts.

“Sharpening a circular saw blade with a file is an art that demands precision and patience. Each stroke counts, and each angle matters. It’s a dance between steel and file, where the harmony of sharpness emerges. Master this skill, and your cuts will sing with effortless precision.”

Nick Schade – Renowned Woodworker

Safety Precautions:

When sharpening a circular saw blade, it is crucial to prioritize safety. This means taking specific precautions to ensure a successful and safe outcome. To begin, wearing appropriate safety gear is important to protect yourself from injury.

Additionally, you should disconnect the saw from its power source and secure the blade with a firm object or workbench to ensure additional safety.

By following these safety measures, you can perform the sharpening task with confidence and avoid any potential accidents.

A. Wear Appropriate Safety Gear

Wearing appropriate safety gear while sharpening a circular saw blade is essential to prevent injuries and ensure optimal performance.

Here are some reasons why wearing safety gear is important:

- Prevents eye injuries from flying debris

- Protects ears from loud noise

- Prevents hand injuries from slipping or accidents

- Protects against inhaling dust and particles

- Prevents clothing from getting caught in machinery

To ensure safety during circular saw blade sharpening, it is recommended to wear the following safety gear:

- Safety goggles or glasses

- Ear protection

- Heavy-duty gloves

- Dust mask or respirator

- Close-fitting clothing without loose ends

By wearing the appropriate safety gear, you can prevent accidents and ensure a safer working environment while sharpening a circular saw blade.

B. Disconnecting The Saw From The Power Source

Detaching the saw from the power source is an essential safety practice when sharpening a circular saw blade. Failure to do so can result in serious injury or death. It is crucial to follow proper procedures when disconnecting the saw to minimize the risk of accidents.

Although disconnecting the saw from its power source is easy to do, the following procedures are given for your convenience:

- Turn off the saw and unplug it from the power source.

- Wait for the blade to come to a complete stop before proceeding.

- Use a wrench to loosen the blade nut and remove the blade.

- Keep the blade in a secure location before sharpening it.

By following these steps, you can ensure a safe and effective sharpening process for your circular saw blade.

C. Securing The Blade And The Saw

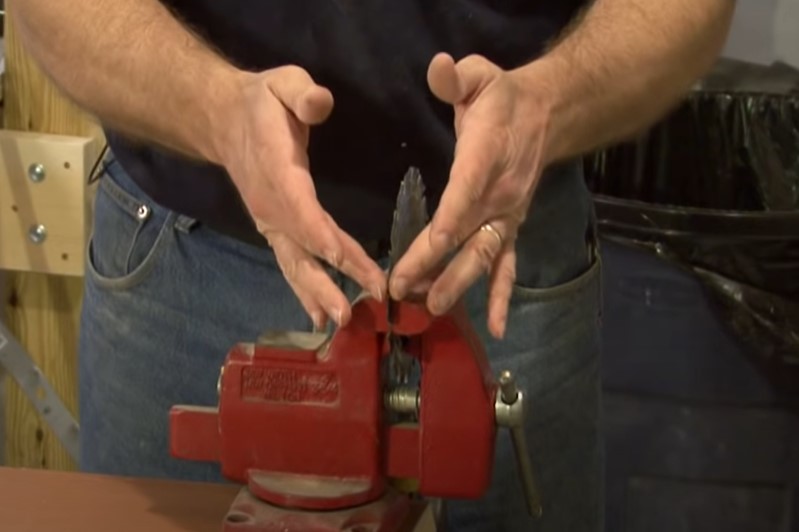

Securing the blade and the saw is critical during the honing of a circular saw blade. To avoid potential hazards and accidents during the sharpening process, it is critical to follow safety measures.

The blade and saw must be firmly secured to prevent them from shifting during the sharpening operation.

To secure the saw blade, use a saw vise or clamp. Before starting, be certain that the saw blade is securely held in the vise or clamp. Wear protective equipment such as safety goggles and gloves at all times.

Choosing The Right File For Sharpening

When it comes to sharpening a circular saw blade, choosing the right files is crucial. Using the wrong file can lead to poor results and even damage the blade.

The type of file needed will depend on the size and number of teeth on the blade. It is important to use a file that matches the tooth shape and angle to ensure proper sharpening.

Additionally, a high-quality file will produce a sharper and more precise edge.

Taking the time to select the correct file and using proper techniques for sharpening will result in a longer lifespan for the blade and improved cutting performance.

Sharpening a circular saw blade with a file is a cost-effective alternative to replacing the blade entirely. With proper technique and maintenance, you can extend the lifespan of your blade and save money in the long run.

A. Different Types Of Files For Circular Saw Blades

Circular saw blades come in different shapes and sizes to cater to varying woodworking requirements. The type of file used for sharpening circular saw blades depends on the blade’s pitch or the distance between two consecutive teeth.

The types of files for circular saw blades are –

- Flat files

- Triangular files, and

- Round files

For coarse tooth blades, a flat file is used, while a triangular file is ideal for finer teethed blades. Similarly, a round file is suitable for sharpening round chainsaw-type cutters, and a chainsaw file is ideal for sharpening chainsaw chains.

Again, you will find three different types of files based on the cut edge. These are –

- Single-cut files,

- Double-cut files, and

- Dimond cut files

Single-cut files are designed for smooth and precise sharpening, while double-cut files are ideal for more aggressive work. Diamond-coated files are the most durable and long lasting, making them an excellent choice for professionals who require the highest quality tools.

It is essential to choose the appropriate file to maintain the blade teeth’ proper shape and angle, ensuring optimal cutting performance and longevity.

B. Selecting The Appropriate File Size

When it comes to sharpening a circular saw blade, choosing the appropriate type of file is crucial for achieving optimal results.

Here are some key points to help you make an informed decision:

- Determine the size of the teeth on your circular saw blade. This will help you choose the right size file.

- Decide on the shape of the file. Triangular files are best for rip-cut blades, while round files are ideal for cross-cut blades.

- Consider the material of the file. Diamond files are more durable and longer-lasting than traditional steel files.

- Take into account the level of experience you have with sharpening saw blades. A beginner may prefer a single-cut file, while a more experienced user may opt for a double-cut file for faster results.

- Always choose a file with the appropriate number of teeth per inch (TPI) for your saw blade.

- Check the manufacturer’s recommendations for the specific saw blade you are sharpening.

Following the above tips will help you to select the right files for your circular saw blades and get the utmost performance and quality.

Preparing The Circular Saw For Sharpening

Before sharpening a circular saw blade, there are several key preparation steps to ensure the blade is in good condition and can be sharpened effectively.

A. Removing The Blade From The Saw:

Firstly, the blade must be removed from the saw and securely clamped in a vice or other stable holding device. This will prevent the blade from moving during sharpening and ensure safety.

B. Cleaning The Blade:

After that, the blade should be thoroughly cleaned to remove any dirt, debris, or rust that may have accumulated on the surface. This will help to provide a clear view of the teeth and improve the sharpening process.

C. Inspecting For Any Damage:

Finally, it is important to inspect the blade for any damage, such as missing teeth or warping, which may require repair or replacement before sharpening can occur.

By taking these preparation steps, a circular saw blade can be sharpened safely and effectively to ensure optimal cutting performance.

Setting Up The Workstation

Once you have removed the blade from the circular saw and cleaned it up, the next task is to set up the workstation. It requires careful consideration and planning while setting up a workstation to sharpen a circular saw blade to get the best.

A. Choosing A Suitable Work Surface

Firstly, it is important to choose a suitable work surface that is flat and stable, such as a sturdy workbench or table. This will ensure that the blade is held in a secure and stable position, allowing for precise and accurate sharpening.

B. Using Clamps To Secure The Blade

It is also essential to use clamps to secure the blade in place to prevent it from moving or shifting during the sharpening process. This not only ensures safety but also improves the quality of the sharpening.

It is important to invest in high-quality clamps that can hold the blade securely in place.

By following these steps, one can set up a professional workstation for sharpening circular saw blades with ease and efficiency.

Proper Technique For Sharpening A Circular Saw Blade With A File

It is critical to use suitable practices when sharpening a circular saw blade in order to get the best results. To get the most out of it, use the tactics listed below.

A. Holding the file correctly:

- Grip the file firmly with your dominant hand.

- Position your hand towards the rear end of the file handle for better control.

- Ensure a comfortable grip to maintain stability throughout the sharpening process.

- Keep your other hand away from the cutting edges and the file path to avoid accidents.

B. Understanding the angle of the teeth:

- Examine the original bevel angle of the teeth on the circular saw blade.

- Take note of the manufacturer’s recommendations or consult the blade’s documentation.

- Typically, the bevel angle for most circular saw blades ranges from 10 to 25 degrees.

- Use a protractor or angle guide to measure and replicate the original bevel angle accurately.

C. Sharpening each tooth individually:

- Start at one end of the blade and work your way across, sharpening each tooth individually.

- Place the file against the cutting edge of the tooth, aligning it with the bevel angle.

- Apply gentle pressure while maintaining the angle and move the file across the tooth smoothly.

- File in one direction only, away from the cutting edge, to avoid causing damage to the blade.

- Repeat the process for each tooth, ensuring consistent pressure and motion.

D. Consistency in the filing motion:

- Maintain a steady and consistent filing motion throughout the sharpening process.

- Avoid applying excessive pressure that could result in uneven sharpening or the removal of too much material.

- Maintain the same filing angle for each tooth to ensure uniformity and proper cutting performance.

- Regularly check the progress of the sharpening by inspecting the teeth and making adjustments as needed.

- Take breaks periodically to rest your hand and maintain accuracy in your filing technique.

Remember, the key to successfully sharpening a circular saw blade with a file lies in holding the file correctly, understanding the angle of the teeth, sharpening each tooth individually, and maintaining consistency in the filing motion.

By following these guidelines, you can effectively restore the sharpness of your circular saw blade and improve its cutting performance.

Maintaining The Correct Tooth Geometry

For constant cutting performance, the correct tooth geometry must be maintained while sharpening a circular saw blade. It aids in maintaining uniform tooth length, ensuring uniform tooth bevel, and preventing excessive blade material removal. Learn how to preserve the proper tooth geometry now.

A. Keeping The Teeth The Same Length:

When sharpening a circular saw blade, it is crucial to maintain the teeth at the same length to ensure consistent cutting performance. Here’s how to achieve this:

- Pay close attention to the filing process for each tooth and ensure that the same amount of material is removed.

- Take breaks intermittently to measure the length of the teeth and compare them to ensure uniformity.

- Use a measuring tool, such as a caliper or ruler, to check the length of the teeth accurately.

- If you notice any variations in tooth length, make adjustments during the sharpening process to maintain consistency.

B. Ensuring The Same Bevel Angle On Each Tooth:

The bevel angle of the teeth plays a crucial role in the cutting efficiency of the circular saw blade. Follow these steps to ensure uniform bevel angles:

- Before sharpening, measure and record the original bevel angle of the teeth to use as a reference.

- Maintain the same bevel angle throughout the sharpening process for each tooth.

- Use an angle guide or protractor to help you achieve the desired bevel angle accurately.

- Double-check the angle periodically to ensure consistency and make adjustments as necessary.

- By maintaining uniform bevel angles, you ensure that each tooth engages the material evenly, resulting in smoother and more precise cuts.

C. Avoiding Excessive Removal Of Material:

While sharpening a circular saw blade, it is crucial to avoid removing excess material from the teeth. This prevents the blade from becoming weakened or causing imbalances.

Consider the following tips:

- Take care not to apply excessive pressure while filing. Apply gentle, consistent pressure to remove just enough material to restore the sharpness.

- Avoid over-filing or spending too much time on any one tooth, as this can lead to uneven tooth geometry and compromised cutting performance.

- Regularly inspect the teeth during the sharpening process to gauge the progress and prevent excessive removal of material.

- If you accidentally remove too much material from a tooth, try to even out the other teeth to maintain balance, or consult a professional if significant damage occurs.

By maintaining the correct tooth geometry, including keeping the teeth the same length, ensuring the same bevel angle on each tooth, and avoiding excessive material removal, you can effectively restore the blade’s cutting performance and prolong its lifespan.

Remember to work attentively and methodically during the sharpening process, ensuring uniformity and precision in the tooth geometry.

Inspecting The Sharpened Blade

Inspecting the sharpened blade of a circular saw is an important procedure that should be carried out regularly to ensure optimal cutting performance. During this process, two key aspects must be thoroughly checked to ensure the blade’s effectiveness.

A. Checking For Consistent Tooth Height

Firstly, the tooth height must be consistent across all teeth. Any variation in tooth height can result in an uneven cut, which could affect the quality of the workpiece.

B. Verifying The Sharpness

Secondly, the sharpness of the blade must be verified to ensure that it is capable of cutting through materials with ease. A dull blade can cause unnecessary strain on the motor, leading to damage and a shorter lifespan.

By meticulously inspecting the sharpened blade of a circular saw, one can ensure that the tool is operating at peak performance and delivering high-quality cuts.

Reinstalling The Blade

It’s time to put the blade back in the circular saw after carefully sharpening and inspecting it. To ensure a high-quality cutting experience, take extra care when reinstalling the blade, including properly aligning the blade and tightly tightening the arbor nut.

In addition, you should take all necessary safety procedures, including donning safety gear and turning off the power source.

A. Aligning The Blade Correctly

Aligning the blade correctly when reinstalling it in a circular saw is crucial for ensuring optimal performance and safety. For that, adhere to the procedures below.

- First, ensure that the saw is unplugged and the blade guard is securely locked in place.

- Then check the blade for any signs of damage or wear, and if necessary, replace it.

- Next, loosen the arbor nut and remove the old blade (if installed).

- Clean the arbor and blade washer thoroughly before placing the new blade on the arbor.

- Ensure that the teeth of the blade face in the correct direction as indicated on the edge.

B. Tightening The Arbor Nut Securely

Once the blade is properly aligned, tighten the arbor nut securely using a wrench or pliers. Be sure to tighten the nut enough to prevent the blade from slipping during use, but avoid over-tightening, as this can damage the blade or the saw itself.

Finally, check the blade for wobbling or misalignment before using the saw.

Always follow the manufacturer’s instructions and safety guidelines when working with power tools.

Testing The Sharpened Blade

After a circular saw blade has been sharpened, it is essential to perform rigorous testing procedures to ensure that the blade is functioning correctly. The testing process will typically involve checking the blade’s flatness, balance, and tension, making a test cut on scrap wood, and evaluating the cutting performance.

A. Check the Flatness, Balance, And Tension

The flatness of the blade is evaluated by using a straight edge to check for any deviations from a perfectly flat surface.

The balance of the blade is checked by suspending it on a specialized jig, which will rotate the blade to test for any vibrations.

The tension of the blade is checked by measuring the deflection in the blade when a force is applied to it.

B. Making Test Cuts On Scrap Wood

It is important to test the cutting performance of a circular saw blade after sharpening to ensure that it functions effectively. One way to do this is by making test cuts on scrap wood, which allows for a practical assessment of the saw blade’s sharpness and precision.

The test cuts should be made at different angles and depths to evaluate the blade’s versatility.

C. Evaluating The Cutting Performance

Once the test cuts have been made, the cutting performance should be evaluated based on the quality of the cuts. Factors to consider include the smoothness of the cut, the accuracy of the cut, and the amount of force required to make the cut.

Through thorough testing, a circular saw blade’s sharpening can be validated, ensuring the blade is safe for use.

Tips For Circular Saw Blade Maintenance

As any professional knows, maintaining your tools is essential for their longevity and effectiveness. Circular saw blades are no exception. To ensure the best results and avoid damage to both the blade and the materials being cut, it is important to adhere to proper maintenance techniques.

To conduct the proper maintenance, you should consider the following issues.

A. Cleaning The Blade After Each Use

Firstly, cleaning the blade after each use is imperative. This can be done with a soft-bristled brush or cloth and a blade cleaner.

B. Proper Storage Of The Blade

Secondly, proper storage of the blade is crucial to prevent rust and damage. It is recommended to keep the blade in a dry and cool place, away from direct sunlight and moisture.

Blades should also be stored in their original packaging or a specialized blade case to prevent damage and ensure proper edge retention.

By following these tips, circular saw blades will perform optimally for years to come.

Sharpening a circular saw blade with a file is just one aspect of maintenance. Regular cleaning, proper storage, and periodic inspections of the blade’s condition contribute to its longevity and cutting efficiency.

FAQs On How To Sharpen A Circular Saw Blade With A File

Q1: How often should I sharpen my circular saw blade?

Sharpening your circular saw blade is an essential aspect of maintenance, but the frequency at which it should be done can vary depending on several factors.

Generally, it is recommended to sharpen your circular saw blade every 3-6 months or after every 10-20 hours of use. However, this frequency may need to be adjusted if the blade is being used heavily or on particularly tough materials.

It is important to keep an eye on the blade’s performance and sharpness and to sharpen it as needed to ensure optimal cutting results.

Q2: Can I sharpen a carbide-tipped circular saw blade?

Sharpening a carbide-tipped circular saw blade can be a challenging task and requires specialized equipment and expertise. While it may be possible to sharpen these blades manually with a sharpening file, it is not recommended as it can easily damage the carbide teeth.

Instead, it is recommended that you take your carbide-tipped circular saw blade to a professional sharpening service. They have the necessary equipment and expertise to sharpen your blade to its original sharpness and ensure that it is ready for use.

Attempting to sharpen your blade yourself can result in poor performance and potential safety hazards, so it is best to leave it to the professionals.

Q3: Is it better to sharpen or replace a dull blade?

When it comes to dealing with a dull blade on a circular saw, the question of whether to sharpen or replace it depends on various factors.

- Firstly, consider the extent of the damage to the blade. If the damage is minor, sharpening the blade could be a cost-effective option. However, if the blade is severely damaged, it’s best to replace it.

- Secondly, consider the frequency of use. If you use the saw frequently, it may be better to replace the blade since sharpening it frequently can reduce its lifespan.

- Lastly, keep in mind the quality of the blade. If it’s a high-quality blade, it’s worth investing in sharpening services to extend its life.

Ultimately, the decision should be based on assessing the level of damage, frequency of use, and the quality of the blade.

Q4: Can I use a bench grinder instead of a file for sharpening?

When it comes to sharpening a circular saw blade, the use of a bench grinder instead of a file can be a viable option. A bench grinder is designed to remove material from a surface quickly and efficiently, making it a powerful tool for sharpening blades.

However, it is important to note that using a bench grinder requires a certain level of skill to ensure that the blade is sharpened evenly and does not become too hot, which can cause damage to the blade.

Additionally, a bench grinder may not be suitable for all types of circular saw blades, so it is essential to consult the manufacturer’s recommendations before attempting to sharpen the blade.

Overall, using a bench grinder for sharpening a circular saw blade can be effective, but it requires caution and knowledge of the tool.

Q5: Can a dull circular saw blade be dangerous to use?

Using a dull circular saw blade can be extremely dangerous and is not recommended. A dull blade can cause the saw to bind or kick back, which can result in serious injury.

A dull blade also requires more force to cut through materials, which can cause the saw to overheat and potentially cause a fire.

In addition, a dull blade produces more sawdust and debris, which can obstruct the operator’s view of the cutting area and increase the risk of injury.

It is important to regularly inspect and replace dull blades to ensure the safe and efficient operation of the saw.

Q6: Are there any alternatives to hand-sharpening circular saw blades?

While hand-sharpening is a common practice for sharpening circular saw blades, it requires a great deal of skill and time. Fortunately, there are alternatives to hand-sharpening circular saw blades.

One alternative is using a sharpening machine, which can quickly and efficiently sharpen the blade to the desired degree.

Another option is using diamond honing tools, which can hone the blade to a razor-sharp edge.

Additionally, there are professional saw blade sharpening services available that use specialized equipment to sharpen blades quickly and accurately.

Ultimately, the choice of method will depend on the needs of the specific project and the available resources.

Conclusion

And there you have it, folks! Sharpening your circular saw blade with a file is not rocket science. It’s a simple process that anyone can do at home with the right tools and a little bit of patience.

By following the steps we outlined in this post, you can save yourself time and money by not having to replace your blade every time it gets dull.

So next time you hear that annoying sound of a dull blade cutting through wood, don’t fret, just grab your file, and sharpen it like a pro!

Related Posts

How To Use A Circular Saw As A Table Saw?

Which Saw Should I Use For DIY Projects?

How To Make A Plunge Cut With A Jigsaw?

What are 5 Uses For A Circular Saw?

Recent Posts

10 Simple Steps to Cut a STRAIGHT Line with a Jigsaw: Fun and Precision!

Have you ever tried to cut a straight line with a jigsaw and found it tricky? Don’t worry, because today we’re going to learn how to do it perfectly. Cutting a straight line is not only fun but...

To use the Ryobi circular saw with laser, simply follow these steps: First, adjust the depth of the blade and set the angle you want to cut. Then, turn on the laser guide by pressing the switch, line...