Reciprocating saw blades are not universal. It is essential to ensure compatibility with the saw before purchasing.

Reciprocating saw blades are widely used in construction and demolition projects to cut through a variety of materials such as wood, metal, and plastic. As a result, selecting the appropriate blade is critical. Despite the popularity of reciprocating saw blades, they are not interchangeable.

Before buying, users should ensure that they are purchasing the right blade for their specific saw. Compatibility should be checked by cross-referencing the model number of the saw with the blade specifications. With the correct blade, users can quickly complete work, prevent accidents, and prolong the lifespan of their tools.

This article will discuss how to choose the right blade for your reciprocating saw and provide an overview of the types of blades available on the market.

Are Reciprocating Saw Blades Universal Fit?

Reciprocating saw blades are mostly universal and interchangeable among different reciprocating saws. The shank of reciprocating saw blades is standardized to fit all reciprocating saws.

However, there may be some exceptions where certain blades only work with specific brands or models of reciprocating saws. It is important to consider the tang size of the blade, as it needs to match the adjustability of the saw.

Overall, when choosing reciprocating saw blades, it is advisable to check the compatibility with your specific saw model or consult the manufacturer’s recommendations.

Types Of Reciprocating Saw Blades

Reciprocating saws are versatile power tools designed to cut through various materials with speed and precision. They are an essential tool for DIY enthusiasts and professionals alike. However, choosing the right blade for the job can be a daunting task, especially for those new to reciprocating saws.

Are reciprocating saw blades universal? The answer is no. There are different types of blades for different cutting jobs.

Here, we will explain the various types of reciprocating saw blades and their pros and cons.

Wood Cutting Blades

Wood cutting blades come in different shapes and styles, but they all have a few things in common: their teeth are large and have wide gaps between them, and they are suitable for cutting through wood, plastic, and other soft materials.

Here are some advantages and disadvantages of using wood cutting blades:

Advantages:

- Fast cutting speed.

- Smooth cuts.

- Easy to control.

Disadvantages:

- Not suitable for cutting through metal or masonry materials.

- Teeth can dull quickly when cutting through hardwoods.

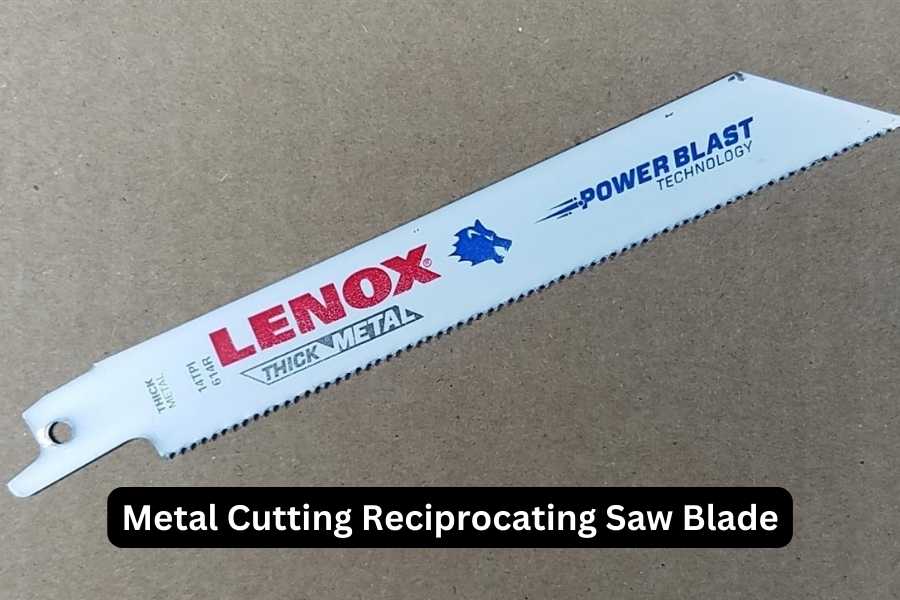

Metal Cutting Blades

Metal cutting blades are designed to cut through various metals, including steel, iron, and aluminum. They are made from high-carbon steel or bi-metal, which consists of a high-speed steel edge bonded to a flexible steel body.

Here are some pros and cons of metal cutting blades:

Advantages:

- Can cut through thick metal materials.

- Long-lasting blades.

- Can withstand high temperatures.

Disadvantages:

- Slower cutting speed than wood cutting blades.

- Can produce jagged cuts on softer metals.

- Not suitable for cutting through masonry materials.

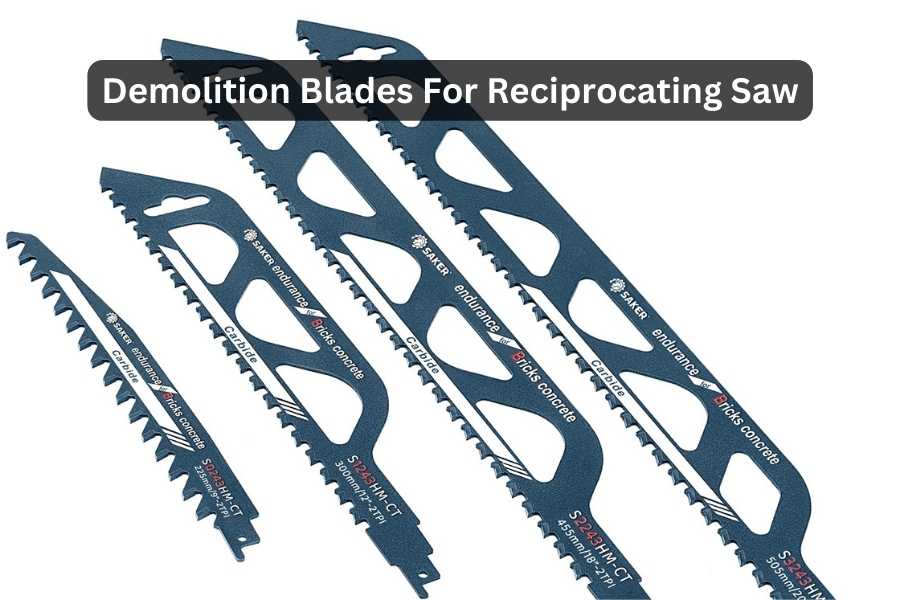

Demolition Blades

Demolition blades are the go-to choice for heavy-duty cutting jobs, such as demolition work and cutting through walls. They are typically wider and thicker than other blades, with large teeth that can cut through nails and other obstructions.

Here are some advantages and disadvantages of using demolition blades:

Advantages:

- Can cut through almost anything.

- Long-lasting blades.

- Great for demolition work.

Disadvantages:

- Difficult to control.

- Coarse cuts.

- Not suitable for precision cuts.

Specialty Blades

Specialty blades are designed for specific cutting tasks, such as pruning trees or cutting tiles. They come in different shapes and sizes, and their teeth are spaced differently for different materials.

Here are some pros and cons of specialty blades:

Advantages:

- Designed for specific cutting tasks.

- Can produce precise cuts.

- Suitable for unique materials.

Disadvantages:

- Expensive.

- Not suitable for general cutting tasks.

Choosing the right blade for your reciprocating saw is crucial for getting the job done quickly and efficiently. Each blade type has its own advantages and disadvantages, so it’s essential to know what you’re cutting before choosing a blade.

Compatibility With Reciprocating Saw Brands

Reciprocating saws are popular for their versatile cutting abilities, and the blades are a crucial component for their success. It is essential to use the right blade for the task at hand to ensure maximum performance and safety.

With various reciprocating saw blade brands in the market, it begs the question: are the blades compatible across different brands?

Let’s explore this topic further.

Compatibility With Reciprocating Saw Brands:

Different brands design their saw blades with specific features that are unique to their products. The result of this is that not all saw blades are compatible across different brands.

Here are a few things to keep in mind when mixing and matching saw blades across brands:

- Some saw blade brands produce blades that fit multiple brands of saws. Before purchasing a blade, make sure to check the packaging to see what brands it fits.

- There may be differences in the way the blades attach to the saw mechanism, meaning that some blades might not fully seat or remain securely fastened. Always ensure you have the correct blade clamp for the blade you are using.

Comparison Between Popular Brands Like Dewalt, Milwaukee, And Bosch

Dewalt, Milwaukee, and Bosch are some of the most popular brands in the market. Although they offer different blade designs, their saw blades are still often interchangeable across their reciprocating saw models.

It is essential to check the packaging or consult your manufacturer’s manual before buying a blade to ensure compatibility.

Common Issues With Compatibility And How To Solve Them

As mentioned earlier, compatibility issues can arise when using saw blades across different brands. Here are some common issues and solutions:

- The blade may not fit perfectly or within the manufacturer’s instructions for adjustment. Always make sure to double-check the compatibility before purchasing the blade.

- An out-of-balance blade can cause reduced cutting performance and vibration, which can damage the saw. Always replace blades when they show signs of warping.

- Dull blades, blades with damaged teeth, or those that are too short or too long for the saw can cause poor cutting performance. Ensure you have the right blade for the job at hand.

It is essential to understand that reciprocating saw blades are not universal across all brands. Always check the packaging and ensure compatibility with your manufacturer’s manual before purchasing or using a blade.

With this information, you can confidently select the right blade for the job and ensure maximum performance and safety.

Reciprocating Saw Blade Lengths

Reciprocating saw blade length plays a vital role in the cutting performance of your saw. It determines the cutting depth, speed, and precision.

That’s why understanding the importance of blade length is critical before purchasing one for your saw.

- Shorter blades: Are ideal for short and precise cuts such as trimming pipes and cutting nails

- Medium blades: Can easily cut through wood, plastic, and metal up to 3/16 inch thickness

- Longer blades: Are perfect for extended cuts such as pruning trees, cutting metal pipes, and demolition work

Different Blade Lengths And Their Uses

Reciprocating saw blades come in different lengths and designs.

Here are some common blade lengths and their uses:

- 3-4 inch blades: These are suitable for cutting through thinner materials such as pipes, nails, and thin metals. You can use both bi-metal and carbide-tipped blades with this length.

- 6-inch blades: Come in handy when cutting through materials up to 3 inches (ca. 8 cm) thick. They are ideal for general-purpose cutting such as pruning trees, cutting wood, and metal.

- 9-inch blades: These are longer blades that are perfect for demolition work. You can use them to cut through thicker metal pipes, wood, and other materials.

Can Longer Blades Cut Faster?

Choosing the right blade depends on the cutting task at hand. However, there’s often a debate on whether longer blades cut faster than shorter blades. While it may seem logical that longer blades cut faster than shorter blades, it’s not always the case.

The cutting speed depends on other factors such as the saw’s speed, blade design, and the material being cut.

Understanding your cutting needs is critical when choosing a reciprocating saw blade. Whether you’re a DIY enthusiast or a professional, selecting the right blade length and design can make your cutting tasks more comfortable and efficient.

Reciprocating Saw Blade Teeth

Reciprocating saws are versatile power tools that make demolition, remodeling, and construction projects a breeze. However, selecting the most suitable saw blade for the task can be challenging, especially for beginners.

Here, we will tackle one fundamental aspect of reciprocating saw blades- their teeth configuration. By the end of this guide, you’ll be able to determine the best blade for your particular project.

Different Tooth Configurations And Their Applications

Reciprocating saws blades come with different teeth configurations. The most common types of teeth are:

- Pruning blades: These blades have fewer teeth, spaced farther apart, meaning they are not ideal for cutting metal. Pruning blades are designed to cut through wood, tree branches, and other natural materials.

- Metal cutting blades: Metal cutting blades consist of tightly spaced teeth that can cut through thick metals such as steel. However, the blades tend to wear out faster when used to cut through tough materials.

- Demolition blades: If you plan to cut through a variety of materials such as wood, metal, drywall, plastic, brick, and plaster, then demolition blades are ideal for your job. These blades have a variable set of teeth that easily tear through different types of materials.

Variable-Pitch Vs. Straight-Set Teeth

Reciprocating saw blades also come in two different configurations: variable-pitch and straight-set teeth.

Variable-pitch teeth blades have teeth that are angled in a way that reduces vibration and enhances smoother cutting. Variable-pitch teeth blades are ideal for cutting thin metals and pipes.

Straight-set teeth blades have teeth that are equally spaced apart, promoting more vigorous cuts but also more vibration. Straight-set teeth blades are perfect for cutting through wood and other natural materials.

The Effects Of Tooth Count On Cutting Speed And Smoothness

Reciprocating saw blades with more teeth tend to produce smoother cuts but are slower. Blades with fewer teeth cut through materials faster, but the cuts may be rough and not cut as straight as blades with smaller gaps. In general, the more teeth a blade has, the smoother the cut, and the fewer teeth a blade has, the faster the cut.

It’s essential to understand the various aspects of reciprocating saw blade teeth configuration to get the best out of your saw and blades. Choose the appropriate blade according to the material you will be cutting, and take into account your desired speed and smoothness of the cut.

Now that you have a basic understanding of reciprocating saw blades, you can confidently select the blade type that works efficiently for your project.

How To Choose The Right Reciprocating Saw Blade

It is common knowledge that choosing the appropriate reciprocating saw blade is essential to achieve optimal cutting results for your projects. However, how can one select the appropriate blade? Let’s find out by reading further.

Know The Type Of Material To Be Cut

Choosing the right blade for a reciprocating saw is an essential task that can impact the longevity of the tool and its efficiency. The blade type determines the material it can cut, the quality of the cut, and how long it will last.

- It is crucial to identify the material you will be cutting to select the proper blade.

- The type of blade you use depends on whether the material is wood, metal, or masonry.

- Using the wrong blade for the material can damage both the blade and the saw, and result in an inefficient cut.

Various Factors To Consider For Blade Selection

When choosing a reciprocating saw blade, several critical factors will determine the success of the job.

- The length of the blade is a crucial factor to consider when purchasing a reciprocating saw blade. Longer blades offer a more extended reach, while shorter blades offer more exceptional control.

- Teeth per inch (TPI) plays an essential part in blade cutting performance. Blades with a lower TPI will cut faster and make a rougher cut, while those with a high TPI will result in a smoother cut.

- The thickness of the blade also influences the blade’s ability to cut through specific materials, and thicker blades will last longer.

Using The Right Blade For Specific Applications

Reciprocating saws are versatile tools that can handle various jobs, and blade selection is essential to ensure the best results.

- Wood-cutting blades have aggressive teeth that are designed for fast cuts, and they typically have a low TPI.

- Metal cutting blades have a higher TPI and are designed to make precise and accurate cuts.

- Masonry cutting blades require heavy-duty teeth that can cut through rough surfaces with ease.

- Specialty blades are also available for use in specific applications such as demolition, pruning, and flush cutting.

Choosing the right reciprocating saw blade can mean the difference between an easy, efficient cut or a frustrating, time-consuming job. By considering the material, important factors, and blade type for the job, you can successfully choose the right blade for every application and achieve professional results.

Care And Maintenance

Cleaning And Storing Reciprocating Saw Blades

Proper care and maintenance are critical for keeping reciprocating saw blades in good working condition.

Here are the key points to remember on cleaning and storing saw blades:

- Always unplug the saw or remove the battery before cleaning the blades to prevent any accidental starting.

- Use a clean rag or wire brush to wipe off any debris or sawdust from the blade. For hard-to-reach areas, use a soft-bristled brush.

- To remove rust or other adhered materials, soak the blade in a solution of vinegar or rust remover. Be sure to rinse the blade thoroughly with water and dry it before storing it.

- Store the blades in a clean, moisture-free area. You can use the original packaging, and a carrying case, or hang them on a pegboard.

How To Sharpen Dull Blades

A dull reciprocating saw blade can make your cutting jobs more frustrating and less efficient. Sharpening the blades is an effective and budget-friendly way to maintain their performance.

Here are the key points to remember when sharpening saw blades:

- Before sharpening, identify the type of blade you have. Not all blades are sharpenable or worth sharpening.

- You can sharpen the blade using a hand file, power grinder, or reciprocating saw blade sharpener.

- Follow the blade’s angle to maintain its integrity while sharpening.

- Take breaks frequently while sharpening to avoid overheating or damaging the blade.

- After sharpening, clean off any debris or metal shavings from the blade.

Proper Lubrication Techniques

Proper lubrication can extend the lifespan of saw blades and enhance their performance. Here are the key points to remember when lubricating reciprocating saw blades:

- Use a lightweight oil or lubricant like wd-40 to lubricate the blade teeth.

- Apply lubricant before and after each use to prevent rust and reduce the blade’s wear and tear.

- Clean any excess lubricant off the blade with a soft cloth or rag.

While not all reciprocating saw blades are universal, proper care and maintenance are necessary to keep them performing at their best.

By following these care and maintenance tips, you can ensure that your blades remain sharp, rust-free, and in good working order for your next project.

Are Sawzall Blades Interchangeable For Other Brands?

Frequently Asked Questions Of Are Reciprocating Saw Blades Universal

Are Reciprocating Saw Blades Universal?

Reciprocating saw blades are not universal, as there are different types of blades for different applications.

What Are The Different Types Of Reciprocating Saw Blades?

There are wood-cutting, metal-cutting, demolition, and blade sets for various materials available.

How Do I Choose The Right Reciprocating Saw Blade?

Consider the material to be cut and select a blade with the required teeth per inch (TPI) count.

Can I Use A Metal-Cutting Blade To Cut Wood?

Using a metal-cutting blade to cut wood is not recommended, as the teeth are designed for different applications.

Which Type Of Blade Is Best For Cutting Thick Metal?

When cutting thick metal, you’ll want to choose a bi-metal blade with a lower TPI (e.g., 8 TPI) to provide greater durability and strength.

Furthermore, consider the thickness and hardness of the metal you’ll be cutting and select a blade that can handle those factors.

Can I Sharpen My Reciprocating Saw Blades?

It is not recommended to sharpen reciprocating saw blades as it can affect the TPI count, causing the blade to be less effective.

How Long Does A Reciprocating Saw Blade Last?

The lifespan of a reciprocating saw blade depends on the material being cut and frequency of use but typically lasts between a few hours to a few weeks.

What Are The Common Uses For Reciprocating Saw Blades?

Reciprocating saw blades are commonly used for demolition, cutting pipes, trimming trees, and cutting metal and wood.

Can I Use Any Brand Of Reciprocating Saw Blade With My Saw?

It is recommended to use blades from the same manufacturer as the saw, but compatible blades from other brands are also available.

How Do I Change A Reciprocating Saw Blade?

Turn off the saw, push the blade release button, remove the old blade, insert the new blade, and release the button.

Conclusion

After a thorough analysis of the reciprocating saw blades, we can conclude that while some blades might be compatible with a wide range of saws, there is no such thing as a universal blade that fits all saws. It is important to carefully match the right blade with the right saw to achieve the best results and avoid any potential hazards.

Taking time to read the labels and specifications of both the saw and blade are crucial to ensure safety and efficiency. Understanding the variations and types of blades on the market can also allow you to select the best blade for the job in terms of material, size, and tooth arrangement.

Remember, investing in high-quality blades that are specifically designed for your saw can ultimately save you time, money, and headaches in the long run.

Recent Posts

Woodworking in 2025 is all about efficiency, precision, and smart technology. Whether you're a beginner or a seasoned craftsman, having the right tools can make all the difference. Here are the top 7...

Ever tried drilling into a piece of wood only to end up with a splintered mess or a wobbly hole? Yeah, it's more common than you think. Wood might seem like an easy material to work with, but...