If you’re a woodworker or a DIY homeowner, there’s a good chance you’ve encountered the frustration of your circular saw stopping mid-cut. It can happen for a few reasons, such as a dull blade, a malfunctioning motor, or a damaged power cord. It’s essential to identify the cause for proper troubleshooting.

This common problem can be not only annoying but also time-consuming and potentially dangerous. In this article, we’ll delve into the various reasons why your circular saw might be acting up and offer practical solutions to keep your projects running smoothly.

Understanding Your Circular Saw

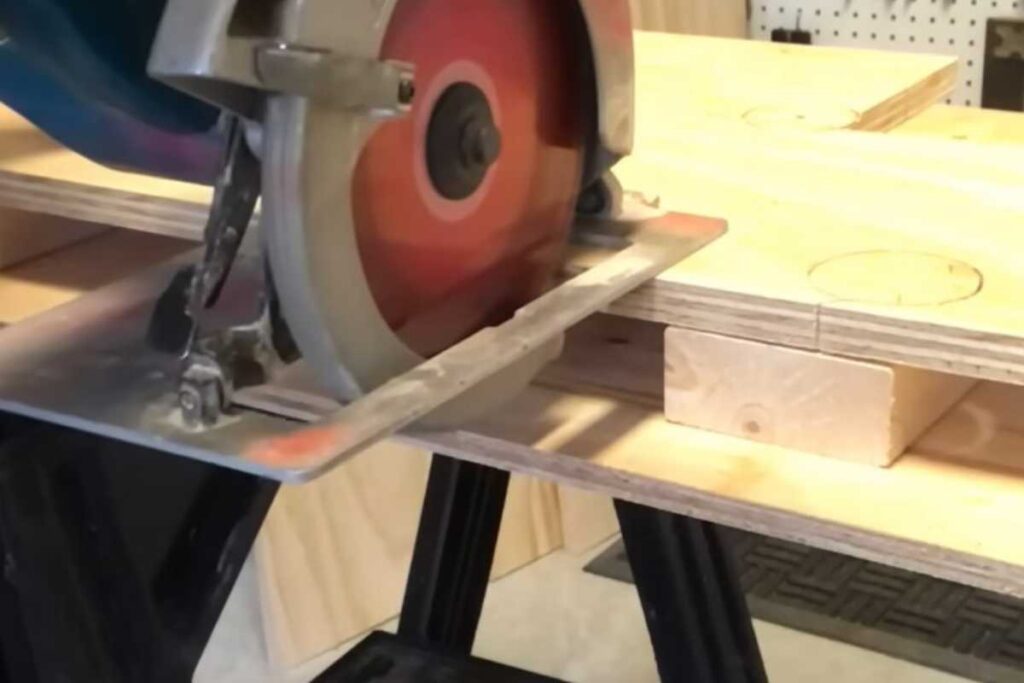

Before diving into the problems, it’s essential to understand how a circular saw works. This tool uses a toothed or abrasive disc or blade to cut different materials by spinning around an arbor. The operator pushes the saw through the material to make the cut.

Common Reasons for Stopping

A circular saw can stop for several reasons. Understanding these can help you troubleshoot effectively. Let’s break down the most common causes:

Blade Issues

The blade is the most important part of a circular saw, and if it’s not performing correctly, it can cause your saw to stop. Dull blades, bent blades, or loose blades can cause the saw to lose power and stop.

Dull Blade

One of the most frequent reasons a circular saw stops is a dull blade. When the blade is dull, it struggles to cut through the material, causing the saw to stall. Regularly check and replace the blade as needed.

Wrong Blade Type

Using the wrong blade for your material can also cause problems. Ensure you’re using a blade suited for the material you’re cutting—whether it’s wood, metal, or plastic.

Blade Binding

Blade binding happens when the cut material pinches the blade, causing the saw to stop. This often occurs if the material is not properly supported or if the blade is misaligned.

Power Problems

A circular saw is a powerful tool that requires a consistent power supply to function correctly. An insufficient power supply can cause the saw to stop working, even during the initial start-up stage.

Here are a few factors you should consider when your circular saw keeps stopping.

Insufficient Power Supply

Ensure your saw is connected to a power source that provides sufficient voltage. An extension cord that’s too long or too thin can result in a drop in power, causing the saw to stop.

To ensure that your saw has enough electricity, you should first check the power source and your extension cord. You can take the following measures as initial troubleshooting:

- Check the saw’s power cable to make sure it is properly plugged in.

- Make sure the power source can supply consistently high voltage and current to your saw.

- Use a voltmeter to check the electrical current flowing through the cord.

- Avoid using too many tools simultaneously, since overloading the circuit can cause an insufficient power supply.

Besides the above, you should also be careful when choosing an extension cord for your circular saw. Always choose the correct gauge, length, and electrical rating. The best cord for your saw should be comprehensive enough to handle the current draw from the motor.

Battery Issues

For cordless circular saws, a weak or drained battery can cause the saw to stop. Make sure your batteries are fully charged and in good condition.

Motor Overload

Pushing the saw too hard through the material can overload the motor, causing it to shut down to prevent damage. This is a built-in safety feature but can be frustrating if it happens frequently.

Overheating

Overheating is another common issue. Continuous use without breaks can cause the motor to overheat, leading to automatic shutdown. Ensure proper ventilation and take breaks to let the motor cool down.

Some common reasons of motor overheating are:

- Heavy workload

- Continuous use without breaks

- Dust and debris buildup

- Lack of maintenance

- Poor ventilation

However, as a saw user, you take the following measures to reduce the chance of overheating:

- Take regular breaks: If you’re working on a large project, take breaks to allow the saw’s motor to cool down.

- Clean the saw: Clean your saw regularly to prevent dust and debris build-up. A clogged saw can cause overheating.

- Monitor the cutting depth: Don’t force the saw too deeply into the wood. Cutting debris can build up on the surface, making it harder for the blade to move and causing overheating. Ensure the saw’s depth of cut setting corresponds to the thickness of the material being cut.

User Technique

Incorrect Cutting Technique

Your cutting technique can significantly impact the performance of your circular saw. Applying too much pressure, cutting at an incorrect angle, or moving too quickly can all cause the saw to stop.

Improper Support for Material

Ensure the material you are cutting is properly supported. Unsupported material can cause the blade to bind, leading to stoppage.

Safety Features

When a safety feature is activated, it can cause the circular saw to stop functioning. Here are some reasons why safety features can cause the circular saw to stop:

Blade guard:

The circular saw includes a blade guard, which protects the blade when not in use. This feature can obstruct the blade if it is not in its proper position, causing the motor to stop working.

Power trigger:

The power trigger is a safety feature that controls the on and off function of the saw. When this trigger is not fully engaged or is malfunctioning, the circular saw may automatically turn off for safety reasons.

Blade lock:

The blade lock feature holds the blade securely in place during cutting and changing the blade. If the lock is not fully released, the saw blade cannot rotate, leading to automatic inactivity of the circular saw.

Maintenance Tips

Regular maintenance is crucial for the optimal performance of your circular saw. Here are some tips:

Clean Regularly

Keep your saw clean by removing dust and debris. This helps prevent overheating and ensures smooth operation.

Lubricate Moving Parts

Regularly lubricate the moving parts to reduce friction and wear.

Inspect for Wear and Tear

Periodically inspect your saw for any signs of wear and tear, particularly the blade, power cord, and motor components.

Preventive Measures

Preventive measures can save you time and frustration. Here are some tips to keep your saw in good condition:

Use the Right Blade

Always use the appropriate blade for the material you’re cutting.

Avoid Overloading

Do not force the saw through the material. Let the saw do the work.

Ensure Adequate Power Supply

Use a proper extension cord and ensure your power source is adequate.

Choosing the Right Saw

Selecting the right circular saw for your needs can prevent many problems. Consider factors such as power, blade size, and additional features that might benefit your projects.

Safety Precautions

Wear Protective Gear

Always wear safety goggles, gloves, and ear protection when using a circular saw.

Follow Manufacturer’s Instructions

Read and follow the manufacturer’s instructions and guidelines for safe and effective use.

Keep Work Area Safe

Ensure your work area is clean and free of obstacles that could cause accidents.

Troubleshoot Safety Features

To avoid stopping your circular saw, you can follow these tips to use the safety features like blade guard, power trigger, and blade lock in your circular saw smartly:

- Blade guard: Ensure the blade guard is in its proper position and not obstructing the blade.

- Power trigger: Check if the trigger is engaged and functioning properly.

- Blade lock: Make sure the blade lock is fully released before operating the circular saw.

Conclusion

Understanding why your circular saw keeps stopping and knowing how to address these issues can save you time and frustration. Regular maintenance, proper technique, and choosing the right tools are essential to keeping your saw running smoothly.

By taking these steps, you can ensure that your circular saw remains a reliable companion for all your woodworking and DIY projects.

FAQs

1. Why does my circular saw keep stopping mid-cut?

Several factors can cause your circular saw to stop mid-cut, including a dull blade, insufficient power supply, motor overload, or improper cutting technique. Identifying and addressing these issues can help resolve the problem.

2. How can I prevent my circular saw from overheating?

To prevent overheating, ensure proper ventilation, take breaks during prolonged use, and keep the saw clean from dust and debris. Regularly inspect and maintain your saw to ensure it runs efficiently.

3. What type of blade should I use for cutting hardwood?

For cutting hardwood, use a blade specifically designed for that purpose, such as a carbide-tipped blade with a high tooth count. This will ensure a clean and efficient cut.

4. Can a dull blade damage my circular saw?

Yes, a dull blade can strain the motor and other components of your saw, potentially leading to damage. Regularly check and replace the blade to maintain optimal performance.

5. How do I know if my circular saw is underpowered?

If your circular saw frequently stops or struggles to cut through materials, it might be underpowered. Check the power supply, ensure you are using the correct extension cord, and consider upgrading to a more powerful saw if necessary.

11 WORST CIRCULAR SAW MISTAKES!! And How To Avoid them…(DON’T DO THESE THINGS! Kickback/Binding)

Recent Posts

15 Ga vs 16 Ga Finish Nailer: Which One Is Right for Your Project?

If you're diving into the world of finish carpentry or simply trying to upgrade your home tool kit, you've probably run into the question: 15 ga vs 16 ga finish nailer—what’s the big deal? They...

Woodworking in 2025 is all about efficiency, precision, and smart technology. Whether you're a beginner or a seasoned craftsman, having the right tools can make all the difference. Here are the top 7...