Did you ever think that the house you’re living in how was constructed?

Maybe, or maybe not. Whatever, you’ll be surprised to learn that wood is used to construct over 90% of American homes (according to the Western Wood Products Association) and that woodworkers are the most important part of the process.

Not only houses but also all decorative wooden furniture, doors and windows, paneling, flooring, staircases, kitchen cabinets, chairs, tables, everywhere there is a touch of an enthusiast woodworker. And the weapons they use most to do all these are a hammer and chisel.

Hammers, on the other hand, have become obsolete, and nail guns have emerged into the mainstream as the most effective method of fastening nails. A nail gun is a tool used for the quick and effective driving of a gang of nails. So, if you need to sink thousands of nails every day, consistently and accurately, it is a pleasant choice.

A nail gun can be divided into two types depending on its power source: pneumatic and cordless. The pneumatic types are the most appealing and frequently used of the two. Air compressors are undoubtedly the primary source of their power.

Hi Framer! We now know that a nail gun’s primary source of power is an air compressor. However, there are several different types of air compressors, large and small, industrial and domestic, laboratory, and so on. So, which one is best for a nail gun in particular?

Let’s learn them below.

What Is An Air Compressor?

It’s a system that turns the strength of compressed air into the potential energy it contains.

An air compressor draws air into a storage tank and condenses it as much as possible to increase the pressure. As a result of this action, the air gains kinetic energy. Later, this kinetic energy is pumped into a variety of machinery and instruments, including nail guns, to perform a variety of tasks.

Air compressors are not only limited to the use in the nail guns, but it is also used in a wide range of industries, including power engineering, manufacturing equipment, and valves for various control devices.

But, do you know when people began using an air compressor? Out of 3000 BC. Yeah, sure! You’ve heard rightly. The human lung was the first type of air compressor. People have been using their breath since ancient times to stoke fire by exhaling oxygen.

Although the first hand-held air compressor was invented in 1500 BC, it was used primarily by metalsmiths or blacksmiths. The bellows were replaced later in 1762, when John Smeaton, a professional engineer, invented a water wheel-driven blowing cylinder.

But the journey of a modern air compressor started with John Wilkinson’s hand in 1776. The blasting machine invented by Wilkinson became a model for modern mechanical air compressors.

How Does An Air Compressor Work And Types?

The working principle of an air compressor largely depends on the types of air compressors. However, the basic principle of an air compressor is to pull air, pressurizes it, and store it inside a tank. When the tank’s pressure reaches its maximum permissible limit, the air compressor stops working. The compressed air, then, is stored in the tank until needed to use it.

Now the question is, how does the compression happen? Well, since there are various types of compressors, the answer will vary depending on the mechanism used to compress the air.

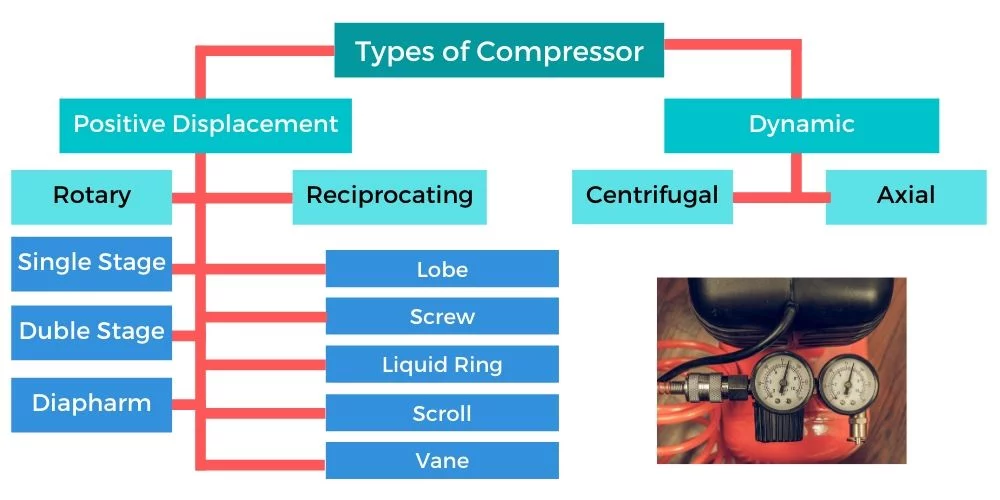

Broadly there are two types of air compressors –

- Positive Displacement, and

- Dynamic.

Positive Displacement Compressor can be divided into two classes –

- Rotary Screw Compressor and

- Reciprocating Compressors.

Rotary Screw Air Compressor

Rotary Screw Air Compressors are the easiest type of air compressors. It has an internal cooling system and doesn’t need much maintenance. When you need continuous operation with high capacity (5hp to 350hp), a rotary screw is best suited there.

Rotary screw air compressors generate energy through two internal rotors spinning in opposite directions. The air is getting stuck between the two reverse rotors, and the pressure rises inside the housing.

Refrigeration cycles, such as chillers, or air-driven equipment, such as jackhammers or impact wrenches, are examples of applications of rotary screw compressors that require significant amounts of compressed gas. It can also be used in areas with a continuous demand for air, such as food packaging industries and automated manufacturing plants.

Reciprocating Air Compressor

The Reciprocating Air Compressor, also known as piston displacement compressor and extensively uses at different small-scale works such as garages and home construction projects. It works just like internal combustion engines, using the movement of piston down-and-up to compress air, store it in a tank, and release it when needed. Reciprocating compressors are available in single or multi-stage variations, which regulate the ranges of pressure they can generate.

Dynamic compressors can be divided into two classes again –

- Centrifugal Compressor, and

- Axial Compressor.

Centrifugal Air Compressor

Centrifugal Air Compressors are using a diffuser to build up potential energy from the air. It has a multi-stage compression system. Due to which it can produce a high amount of energy with a relatively small machine. It is often used in large industries like chemical plants or steel manufacturing factories.

Axial Air Compressor

Axial Air Compressors are also high capacity and are not used in even construction sites. Usually, it is seen being used in high-speed engines like ships or planes.

From the above classification, we may conclude that the reciprocating air compressor or piston air compressors are the kinds that are suitable for small machines. And will also be better suited for air nail guns.

Let’s see the video below to get a glimpse of how do air compressors work –

What Size Air Compressor For Nail Gun?

Typically, pneumatic nailers do not need a constant supply of air. Instead, they need a short burst of air to push nails. As a result, a small portable air compressor is strong enough to operate any nail gun.

We have to know some more basic things to understand the exact size of the air compressor for the nail gun. And they are CFM, HP, PSI, Gallon Capacity, etc.

Usually, the best air compressor for nail guns will have a good balance between the CFM and PSI to get the best output. So, first, we have to determine the CFM rate, PSI, and HP. Then we will head out to measure the size of the air compressor.

What Is The Optimum Flow Rate – CFM

CFM is cubic feet per minute, which means the volume of air that moves or flows from one place to another at a particular time. Therefore, it indicates how fast the air flows from the compressor to the device.

It is important to check the air compressors’ CFM before purchase. Because, if the compressor CFM is lower than the required CFM of your tools, you have to stop your work in the middle and wait until it kickback to its original position.

Let’s find the general formula for calculating the CFM as follows –

- Measure the volume of space in cubic feet. Fill it up with air.

- Then determine the time of the evacuation of the space.

- Then divide the volume by time.

Example: Suppose the size of the room is 1000 ft3, and it’s full of air. Then if it takes five minutes to evacuate the room through an orifice, the flow rate will be 200 CFM.

Volume (1000 cubic feet)/time (5 minutes) = 200 CFM

However, in the case of nail guns, we do not need to follow this intimidating task as the manufacturers predetermine it. Yeah! All the nail guns manufacturer has a recommended CFM. What you need is to calculate the size of the air compressor by matching it with them.

There is simple math again. Multiply the recommended highest CFM rating of your pneumatic nailer by 1.5, that’s it. Suppose the CFM for framing nailer is 2.2, then the required size of the air compressor will be 2.2×1.5 = 3.3 CFM. So, after rounding, the recommended CFM for framing nailer will be 4. Here, this additional CFM gives you a guarantee that the compressor will work efficiently and required less time to refill.

Let’s check the chart below to get the nail gun vs. recommended CFM.

| Nail Gun Types | Av. CFM @ 90 PSI | CFM (Recommended) | Compressor Type |

|---|---|---|---|

| Pin Nailer | 0.3 | 2.0 CFM, 2 Gallon | Pancake/Portable |

| Brad Nailer | 0.3 | 2.0 CFM, 2 Gallon | Pancake/Portable |

| Finish Nailer | 0.5 | 2.0 CFM, 2-3 Gallon | Pancake/Portable |

| Upholstery Stapler | 0.3 | 2.0 CFM, 1 Gallon | Pancake/Portable |

| Sheathing Nailer | 2.0 | 4.0 CFM, 4 – 6 Gallon | Portable |

| Framing Nailer | 2.2 | 4.0 CFM, 4 – 6 Gallon | Portable |

| Roofing Nailer | 2.2 | 4.0 CFM, 4 – 6 Gallon | Portable |

| 2-5 nailers at a time | – | 7.0+ CFM, 6-8 Gallon | Wheelbarrow |

Now, we get the CFM for the nail gun. But to choose the perfect air compressor, still, we have to pass on some other criteria. And our next objective is to know about the air pressure or PSI.

What Is The Relationship Between PSI And CFM?

PSI or pound per square inch is an air pressure measurement unit. It defines how much pressure actually exerted on a square inch of space by the air. To put it more simply, 10 PSI means 10 pounds of wind pressure applied per square inch of area.

CFM and PSI have a strong symbiotic relationship. When all are set to their optimal settings, an air tool can be successfully operated. The flow rate would increase if the air pressure is set lower. As a result, you’ll get more CFM at a lower PSI. On the other hand, higher PSI means the compressor can carry more air in the tank, allowing the air tools to operate for longer.

Therefore, a compressor with a higher CFM and optimum air pressure can produce more air and is best suited for heavy-duty applications, such as running air wrenches and framing nail guns.

To get the best output from a pneumatic framing nail gun, choose an air compressor that can generate at least 4 CFM @ 90 PSI, as opposed to the minimum necessary pressure of 90 psi and flow rate of 2.2 CFM.

Is HP A Matter For Air Compressor?

You may be familiar with the abbreviation HP, which stands for Horsepower and shows the engine’s working ability. Similarly, the HP of an air compressor shows the compressor’s total capacity. In simple terms, it defines how much work the air compressor can do in a given amount of time.

If you can determine the right tank size and CFM rating, you will automatically get the correct HP. So, it need not worry much about the HP of an air compressor like CFM or PSI.

You might assume that the more HP you have, the more productive you are. However, this is not the case in this instance. HP isn’t the only thing that can affect a compressor’s performance. If a 5HP and a 10HP compressor both can provide the same PSI at a constant flow rate, the 5HP compressor would be the more cost-effective option.

As a result, doing more with less HP will save you money and result in higher returns over the compressor’s lifetime.

What Is The Right Tank Size For Nail Gun?

The tank size of an air compressor vastly depends on the projects you are going to handle. If you want to run numerous tools and nail guns simultaneously, then you certainly need a large capacity tank, and the reverse is true for single use.

Worldwide compressor manufacturers are using ‘Gallon’ as a measuring unit for the storage tanks. Smaller tanks — between 4 to 6 gallons — are ideal for many tasks, such as airbrush painting or running framing nailers or other nail guns and wrenches.

On the other side, bigger tanks can carry extra compressed air at higher pressure. These are, therefore, ideal for operating larger projects, such as automotive work and steel manufacturing plants, where required continuous airflow.

Portable Or Stationery: Which One Is Best For Nail Guns?

A portable air compressor is suitable for nail guns due to the nature of the work. Nail guns, such as brad or framing nailers, are used for a variety of outdoor and indoor woodworking activities, including framing, decking, door, and window molding installation, furniture construction, and more. Other nailers, such as roofing or siding nailers, may be used to mount fiberglass shingles to the roof or siding to the framing. They must have adequate air pressure and be portable. So, if your compressor couldn’t hit those far-flung locations, you didn’t complete your project.

As a result, you should choose an air compressor that is not too large. It is also capable enough to meet all of the CFM and PSI criteria for driving nails smoothly. As a whole, a compressor with a tank capacity of 6 to 10 gallons is sufficient for running 3/4 nail guns and is compact enough for easy maneuverability.

However, if you plan to run multiple tools like an impact wrench, an air spray brush, a ratchet, or a sanding machine simultaneously and portability is not an issue, you may go for a big stationary air compressor.

Additional Features Of An Air Compressor To Look For:

In addition to the basic specifications, there might also be some additional features you are looking for when choosing an air compressor:

Air cooling system

The air compressors generate a certain amount of heat during the compression process. Now, if your compressor doesn’t have enough arrangement to keep the machine cool, it can shorten life, even causing an accident. So, check the cooling system before purchase.

Thermal Protection

While air compressors come with a cooling system to protect the machine from being overheated, long-term use can result in malfunction. A thermal protector works automatically to stop the device to secure the compressor from catching fire. So, be sure that your air compressor contains thermal protection system.

Noise level

Once you switch on the compressor machine, you cannot avoid noises, as it is one of the louder machines around us. However, some modern compressor comes with a noise protection shield. Try to check the dB level of the compressor before purchase if you really hate those machine roaring sounds.

Oil-Free Operation

Practically all of the contemporary small air compressors are oil-less, meaning no more worrying about checking or pouring oil. Less oil means less frequent servicing too. An oil-free air compressor, typically, has a shorter life than lubricated ones.

Conclusion

When you plan on pursuing woodworking as a career and want to create a big workshop for potential growth, then the smart choice would be to select a large-capacity air compressor. On the other hand, if DIY is on your mind, a small pancake-style air compressor is good enough. So, the size of an air compressor for a nail gun depends primarily on your strategy and budget.

More Queries to Answer:

Q. Is higher CFM a better air compressor?

CFM and PSI exist a correlation. If PSI goes down, then CFM will go up. And PSI is necessary to properly drive the nails. Nail guns usually required air pressure of up to 120 psi. Therefore, it is easier to use a higher CFM air compressor to control the air pressure. For a framing nailer, it is safer to have four or higher CFM to get optimum pressure to drive nails into wood precisely.

Q. What kind of air compressor do I need for a nail gun?

A pneumatic nail gun is an intermittent power tool, which means it does not require a continuous air supply. Instead of that, a short burst of air is necessary to sink the nails into the wood. So, a portable air compressor with a rating of at least 2 CFM and a capacity of 2 to 6 gallons is good enough to operate a pneumatic nail gun.

Q. Can an impact wrench run on a 6-gallon air compressor?

Of course! It may. But, you know, the minimum airflow requirement to operate an impact wrench is 6-gallon. And using an exact match compressor wouldn’t be a good idea, because you’ll be out of the air in a short time and need frequent refilling. As per the pro advice, it is wise to use a compressor that is 1.5 times higher than the capacity required by the device.

Related Reviews:

- Best Pneumatic Framing Nailer Reviews And Buying Guide [Click here to read more]

- 10 Best Air Compressors For Nail Guns With Buying Tips [Click here to read more]

- All You Need to Know About Different Types of Nail Guns [Click here to read more]

- You’ll be Deprived Of These 7 Benefits If You’re Not Using A Nail Gun [Click here to read more]

Recent Posts

Woodworking in 2025 is all about efficiency, precision, and smart technology. Whether you're a beginner or a seasoned craftsman, having the right tools can make all the difference. Here are the top 7...

Ever tried drilling into a piece of wood only to end up with a splintered mess or a wobbly hole? Yeah, it's more common than you think. Wood might seem like an easy material to work with, but...