Yes, jigsaw blades are generally universal, and they fit most jigsaw brands. Jigsaw blades are designed in such a way that they can firmly fit into the blade clamp of the jigsaw.

The only thing that varies is the blade shank type, which can be either t-shank or u-shank. Jigsaw blades are an essential tool for various tradespeople and DIY enthusiasts. They are versatile and can cut through a variety of materials, including wood, metal, and plastics.

When it comes to jigsaw blades, the one size fits all concept applies, making them very cost-effective and easily accessible. By understanding the shank type, t-shank, or u-shank, you can be able to purchase the right blade for your tool. This guide explores all you need to know about jigsaw blades to help you make a more informed decision when purchasing and using the tools.

Jigsaw Blade Basics

Jigsaws are one of the most versatile power tools in any carpenter’s toolbox. The ability to cut various shapes and curves on different materials like ceramics, wood, metal, and plastics quickly makes it a favorite.

However, do all jigsaw blades fit the same universally? Do you require different types of jigsaw blades for different materials? Let’s delve into the basics of jigsaw blades.

Different Types Of Jigsaw Blades

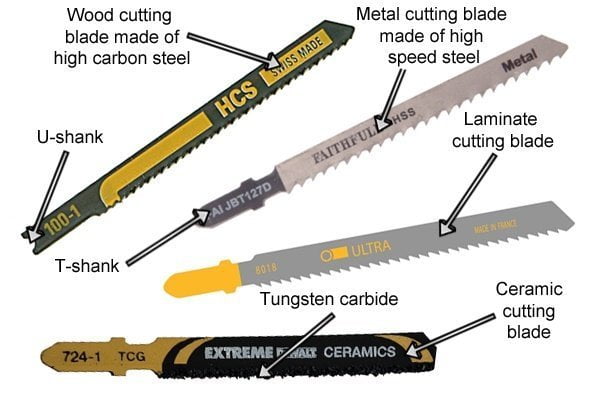

Jigsaw blades come in different shapes and sizes, with each one suited to different materials and cutting applications.

Some of the commonly used jigsaw blades include:

T-shank blades: These blades have a t-shaped shank and are the most common jigsaw blade type used today.

U-shank blades: These blades have a u-shaped shank and were the original jigsaw blade type.

Reverse-tooth blades: These blades have teeth pointing downwards, preventing the top layer of laminates or veneers from chipping.

Down-stroke blades: These blades have teeth pointing downwards, allowing for a controlled and smooth cut through soft materials.

Materials Used In Jigsaw Blades

Jigsaw blades are made from various materials, with each offering different levels of hardness and durability. Some of the commonly used materials include:

High-speed steel (HSS): HSS blades are affordable and ideal for cutting soft metals.

Carbon steel: These blades are economical and useful for cutting wood and plastics.

Bi-metal blades: These blades feature a combination of high-speed steel and carbon steel, making them durable and versatile.

Tungsten carbide blades: These blades are ideal for cutting through hard materials like ceramic tiles, marble, and porcelain.

Diamond-grit blades: These blades feature a diamond grit-coated edge and are perfect for cutting through tough materials like glass and ceramics.

Jigsaw Blade Teeth Configurations

The teeth configuration of a jigsaw blade is an essential factor to consider, depending on the application and material to cut through.

Some common jigsaw blade teeth configurations include:

Wavy set teeth: These blades have wide-spaced, large teeth, making it suitable for ripping cuts on soft materials like wood.

Ground teeth: These blades have finer, closely spaced teeth, making them ideal for cutting intricate curves.

Side-set teeth: These blades are suitable for high-speed rough cuts on soft materials like wood.

Precision-ground teeth: These blades have teeth that are ground to sharp points, allowing for clean cuts on hard and soft materials alike.

Jigsaw Blade Shank Types

Jigsaw blades come with two main shank types, t-shank blades, and u-shank blades.

T-shank blades are the most common and compatible with most jigsaws.

U-shank blades, on the other hand, are old-fashioned, and you’ll find them hard to buy.

Understanding the basics of jigsaw blades is essential to ensure you use the right blade for your project.

Remember to choose a blade with the correct teeth configuration, made of an appropriate material, and with the right shank type.

Compatibility Of Jigsaw Blades

Jigsaws are among the most versatile power tools in any DIYers workshop. These handheld saws can cut through wood, plastic, metal, and even tiles with ease, thanks to their interchangeable blades, which come in various shapes and sizes.

However, with so many jigsaw blades available on the market, it can be challenging to determine their compatibility.

We’ve compiled some essential information to help you better understand the compatibility of jigsaw blades.

Explanation Of Blade Compatibility

When we talk about jigsaw blade compatibility, we refer to the blade’s ability to fit the jigsaw shank. Different jigsaws come with different shank designs, but the two most common types are t-shank and u-shank.

T-shank blades have a tang that fits into a notch in the jigsaw’s clamp. They are compatible with most jigsaws.

U-shank blades have a slot that slides over the jigsaw’s clamp. They are a bit old fashion and not compatible with all the jigsaws available on the market today.

Factors Affecting Blade Compatibility

Here are some factors that affect blade compatibility:

Shank type: Always use the correct shank type. Using the wrong shank can result in wobbling and the blade coming loose.

Blade size: Check your jigsaw manual for the recommended blade size. Using a blade that’s too big can cause damage to the jigsaw and the blade itself.

Material: Different jigsaw blades are designed for specific materials such as wood, metal, and plastic. Using the wrong blade can result in inefficient cuts or worse, damage to both the material and the blade.

Are All Jigsaw Blades Interchangeable?

Not all jigsaw blades are interchangeable. T-shank blades are incompatible with u-shank jigsaws, and vice versa. However, some jigsaws come with adapters that allow using both shank types.

Moreover, some jigsaws have proprietary shank designs, which means that only specific blades from the same brand and model can fit that jigsaw.

Additionally, some blades from third-party manufacturers might fit proprietary jigsaws. Therefore, always check the blade and jigsaw’s compatibility before starting any project.

Brands Offering Universal Blades

Some jigsaw blade manufacturers offer universal blade designs, intended to fit into different jigsaw brands that use the same type of shank. These blades are often labeled as “multi-fit” or “universal.” They might come with adapters that allow the blade to fit different shank types, enabling greater versatility for your jigsaw.

Keep in mind that universal blades can vary in quality and durability; thus, it’s essential to choose a reputable brand and inspect the blade’s build quality before use.

Knowing the compatibility of jigsaw blades is crucial to ensure that your blades fit your jigsaw securely and facilitate efficient cuts.

By understanding the basics of blade compatibility, you can choose the right blade for the material and job.

Always consult your jigsaw manual for the recommended blade type and size, and inspect your blades before and after use to prevent accidents.

With the right blade, your jigsaw can be a versatile and reliable tool in your workshop.

Finding The Right Jigsaw Blade

Jigsaw blades are an essential tool used to make intricate cuts in various materials, including metal, plastic, and wood. Selecting the right jigsaw blade can be challenging, especially with so many different types available in the market.

We will explore the factors to consider when selecting jigsaw blades, such as blade length and width, blade teeth count and configuration, material being cut, and blade shank type and size.

Factors To Consider When Selecting Jigsaw Blades:

When selecting jigsaw blades, consider the following factors:

Blade Length And Width:

- Longer blades are ideal for cutting thicker materials, while shorter blades are used for cutting thinner materials.

- Wider blades are suitable for making faster cuts, while narrower blades are used for making smoother cuts.

Blade Teeth Count And Configuration:

- The number of teeth on a blade determines the blade’s cutting speed, with more teeth producing a smoother cut.

- The configuration of the teeth determines the blade’s suitability for different materials. For instance, blades with fewer, larger teeth are ideal for cutting wood, while blades with more, smaller teeth are suitable for cutting metal.

Material Being Cut:

- The material being cut will determine the type of blade required. For example, a blade with larger teeth is perfect for cutting softwoods, while a blade with smaller teeth is ideal for cutting hardwoods.

- Ensure that you select the appropriate blade for the material being cut to ensure that the blade is not damaged and that the finished product is of the desired quality.

Blade Shank Type And Size:

- A blade’s shank type and size must match the jigsaw’s clamp type and size to ensure a secure fit.

- T-shank blades are widely used as they offer quick and easy blade changes, while u-shank blades are more secure but harder to change.

Selecting the right jigsaw blade is vital to achieving precise and clean cuts. To select the right blade, it’s crucial to know the material you’ll be cutting and consider the blade’s length, width, teeth count configuration, and shank type.

With this knowledge, you can select the perfect jigsaw blade for your project and achieve professional-quality results.

Jigsaw Blade Maintenance

Jigsaws are versatile tools, perfect for intricate cutting and shaping of different materials. Owning a jigsaw is fundamental for any DIY enthusiast, but it is equally important to keep the blade sharp and in good condition.

In this section, we will look at common questions such as whether jigsaw blades are universal and provide maintenance tips to keep your blades in perfect condition.

Tips For Maintaining Jigsaw Blades

To keep your jigsaw blades in good condition, use these maintenance tips:

- Always wear protective gloves while handling jigsaw blades.

- Keep the blades clean and dry after use.

- Lubricate the blade’s teeth with a few drops of oil to prevent rust.

- Store jigsaw blades in a dry and clean place.

- Ensure the blades are compatible with your jigsaw model before purchasing.

- Follow proper usage guidelines in the manufacturer’s manual to avoid damage to the blades.

Cleaning And Storing The Blades

Cleaning and storing your jigsaw blades are critical in preventing rust and extending their lifespan. Here’s how to do it:

- Use a dry and clean cloth to remove any dust or debris on the blade.

- Soak the blade with a small amount of mineral spirits or vinegar if there’s buildup on the blade.

- Gently scrub the blade with a soft-bristled brush or an old toothbrush.

- Rinse the blade thoroughly with clean water and pat it dry with a clean cloth.

- Store the blades in a dry and clean place or container to prevent rust.

When To Replace Blades

Knowing when to replace blades is critical in maintaining the tool’s efficiency and ensuring quality cuts. Here are some signs that it’s time to replace the blades:

- The blade is worn out, broken, or damaged.

- The teeth of the blade are dull or uneven.

- The blade produces jagged cuts.

- The blade starts to vibrate excessively.

Proper Disposal Of Worn-Out Blades

Disposing of worn-out jigsaw blades is just as important as maintaining them. Blades that are not disposed of correctly can cause harm to individuals and the environment. Here’s how to dispose of worn-out jigsaw blades responsibly:

- Do not throw away blades in the trash or recycling bin.

- Place blades in a designated and labeled blade disposal container.

- Take the container to a disposal or recycling center that accepts blades.

- Alternatively, check with your local recycling center for guidance on the proper disposal of blades.

Proper maintenance of jigsaw blades is crucial in keeping the tool functioning effectively and ensuring quality cuts. Follow these simple maintenance tips, and you’ll get the most out of your jigsaw blades.

Frequently Asked Questions On Are Jigsaw Blades Universal

Are Jigsaw Blades Universal?

Yes and no, depending on the type of jigsaw and blade you have. Some blades may not fit all models.

How Do I Know Which Jigsaw Blade To Use?

Check the packaging for the blade to see which type of material it’s designed to cut.

Can I Use A Metal Blade To Cut Wood?

It’s not recommended as metal blades are designed to cut through harder material and may damage the wood or the blade.

Can I Use A Wood Blade To Cut Metal?

No, wood blades are not strong enough to cut through metal and could break or cause injury.

How Often Should I Replace My Jigsaw Blade?

When you notice the blade is beginning to dull, is damaged, or is not cutting effectively, it’s time for a replacement.

Can I Buy Jigsaw Blades In Bulk?

Yes, many brands offer bulk packs of blades in a variety of sizes and types for convenience and cost-effectiveness.

Sum Up: Are Jigsaw Blades Universal?

To sum up, the question of whether jigsaw blades are universal or not is a complex one. While it’s true that jigsaw blades do come in different shapes, sizes, and materials, many are designed to be used across various models.

As such, it is safe to say that some jigsaw blades are universal. However, before purchasing a blade, it is important to check the specifications to ensure that it is compatible with your particular jigsaw. Additionally, it’s important to consider the type of material you will be cutting and choose the appropriate blade accordingly.

Doing so will ensure that you get the best possible results. While some jigsaw blades are universal, it’s always best to double-check compatibility and choose the right blade for the job. By doing so, you’ll be able to complete your cutting tasks more efficiently and effectively.

Related Posts:

- How To Remove Saw Burn Marks From Wood?

- Which Saw Should I Use For DIY Projects?

- How To Use A Jigsaw To Cut Curves?

- Brushless Vs Orbital Jigsaw

Recent Posts

Woodworking in 2025 is all about efficiency, precision, and smart technology. Whether you're a beginner or a seasoned craftsman, having the right tools can make all the difference. Here are the top 7...

Ever tried drilling into a piece of wood only to end up with a splintered mess or a wobbly hole? Yeah, it's more common than you think. Wood might seem like an easy material to work with, but...